Anyone who owns a legendary Porsche 550 Spider, 904 or 356 Carrera can count himself lucky. These cars have experienced an enormous increase in value over the last few years. Unfortunately special parts like cylinder heads are no longer available. In the event of damage, the only remedy is through customized parts reconstruction or reverse engineering, and 3-D printing turned out to be the cheapest way.

Anyone who owns a legendary Porsche 550 Spider, 904 or 356 Carrera can count himself lucky. These cars have experienced an enormous increase in value over the last few years. Unfortunately special parts like cylinder heads are no longer available. In the event of damage, the only remedy is through customized parts reconstruction or reverse engineering, and 3-D printing turned out to be the cheapest way.

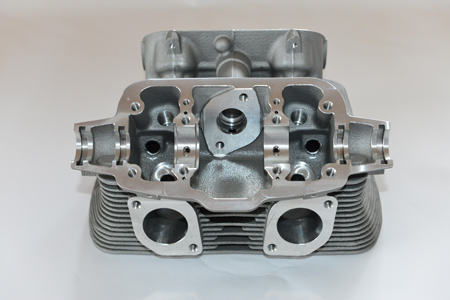

Reconstructing complex components is a challenge for every design engineer, because drawings are not available in most cases and they are not provided by the OEM-manufacturers. In this particular case, the reconstruction of a Carrera cylinder head made of aluminum started with measuring and scanning of the defective head.

Valve guides, seat rings, camshaft bearing, intake and exhaust ducts, cylinder head screws etc. had to be set up as 3D base bodies in a meticulous detailed process. The next step was the transfer to superordinate functional models and the adding of design features from casting technology like site measuring, bevels and fillets.

Affordable sand cores from the 3D printer

After the geometric reconstruction made by the company CAD Support from Mössingen, Germany, the production of the sand cores was the next item on the agenda. The project implementation with conventional cores based on core-making tools was impossible for cost reasons. The only solution was creating the cores in a 3D printer.

The order for printing the entire core package with eleven cores in total went to the voxeljet service center in Friedberg which has many years of experience in project of this kind. Thanks to the excellent printing quality of the voxeljet printer, it was also possible to outline the thin-walled cooling rib measuring 2 mm without additional supporting structure in the inner and outer cores.

The molding was made by the foundry Rauleder & Rudolf based in Schwäbisch Gmünd, which specializes in constructing unique components. The hot isostatic pressing (HIP) treatment led to a tremendous improvement of the mechanical properties, as well as a reduction of pores.

The final T6 heat treatment provided the ultimate strength of the cylinder head. The finishing of the components was made on the basis of the 3D CAD files in a 5-axis machining center. After completion, the aluminum cylinder head was ready for assembly.