Concentrated photovoltaics (CPV) is a photovoltaic technology that generates electricity from sunlight. Contrary to conventional photovoltaic systems, it uses lenses and curved mirrors to focus sunlight onto small, but highly efficient, multi-junction (MJ) solar cells. Despite the need for additional concentrating optics, and the usage of more expensive MJ-cells, CPV systems, and especially High concentrating photovoltaic (HCPV) systems, have the potential to become competitive in the near future. They possess the highest efficiency of all existing PV technologies. And a smaller photovoltaic array also reduces the balance of system costs.

Concentrated photovoltaics (CPV) is a photovoltaic technology that generates electricity from sunlight. Contrary to conventional photovoltaic systems, it uses lenses and curved mirrors to focus sunlight onto small, but highly efficient, multi-junction (MJ) solar cells. Despite the need for additional concentrating optics, and the usage of more expensive MJ-cells, CPV systems, and especially High concentrating photovoltaic (HCPV) systems, have the potential to become competitive in the near future. They possess the highest efficiency of all existing PV technologies. And a smaller photovoltaic array also reduces the balance of system costs.

CPV systems often use solar trackers and sometimes a cooling system to further increase their efficiency. They are currently more expensive and far less common than conventional PV systems. However, ongoing research and development is rapidly improving their competitiveness. Concentrated photovoltaics: challenges

Concentrated photovoltaics: challenges

CPV systems operate most efficiently in concentrated sunlight, as long as the solar cell is kept cool through use of heat sinks.

Diffuse light, which occurs in cloudy and overcast conditions, cannot be concentrated. To reach their maximum efficiency, concentrated photovoltaics systems must be located in areas that receive plentiful direct sunlight.

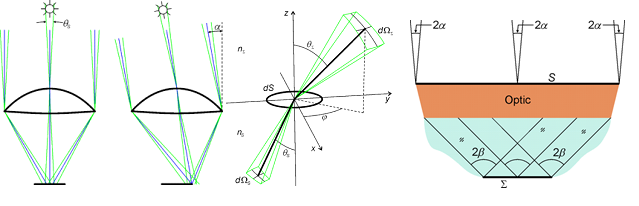

The design of photovoltaic concentrators introduces a very specific optical design problem, with features that makes it different from any other optical design. It has to be efficient, suitable for mass production, capable of high concentration, insensitive to manufacturing and mounting inaccuracies, and capable of providing uniform illumination of the cell.

All these reasons make non-imaging optics the most suitable for concentrated photovoltaics. The problems with imaging optics is that they will focus the light on a specific point, which can cause a specific point of the cell the get an extremely high concentration, causing the sun to burn a hole in the cell. Therefore people will try to find an optimum, that has the highest intensity of light throughout the day onto the cell.

In Photo Voltaics acceptance angles and étendue are very important, whereas in other fields you use optics, you might not even encounter these terms.

With Concentrated Photo Voltaic Cells you would like to optimize your system for the whole day, or even the whole year. Some light loss at a specific time of the day, could be compensated at another. Especially if the panels are placed on a rooftop, or other static mount, without a tracking system.

What LUXeXceL can do?

LUXeXceL can 3D print optics, without any post processing, with a smooth surface straight form the printer, due to our patented technology.

When you would like to test various lenses that you have designed, which look like they will have a good effect in simulation, you would like to test it first in you lab, and later in the field. These are lenses that LUXeXceL technology can help you with, finding out what the best lens shape is in prototyping stages, and first test series.

With our technology iterations are fast and very cost efficient, because we can print iterations at a fraction of the cost of a first prototype. We can also very easily print a lens array with the correct pitch between the optics, making you assembly that much easier. A single lens from an array would also count as just an iteration.

Our USP's

Fast service (<2 weeks)

No upfront investments (no tooling required)

Order to demand (no minimum order quantities)

Affordable small and medium size series

Fast and affordable iteration process

How does this help you?

You can check your optics faster, and therefore shorten your project time, or time to market

You can postpone the investment into tooling until you are certain of your optical design

You can start your first test series with printed optics, until:

You are ready to go to a full scale project

You have proven you concept and have sold it to a business partner

You can order different designs that look good in your simulation software to really see which works best, iterations are at 25%, 20% and 15% of the original proto price, for respectively one, two, three or more iterations. These iterations can be ordered simultaneous, or sequentially.

Additionally we think we can also mean something in:

Large size optics

Lenses with a high # of individual lenslets

Freeform optical surfaces

Looking at real life projects, printing the optimal lens shape for a static mount with a specific orientation, angle of the mounting structure (roof) and latitude could also increase efficiency significantly.

www.luxexcel.com