Visitors to GF Machining Solutions’ stand at EMO Hannover 2019 discovered how SMART wire equipped with radio frequency identification (RFID) chips can help them realize the full potential of their AgieCharmilles CUT P series wire-cutting Electrical Discharge Machining (EDM) solutions and achieve Industry 4.0-level process control.

Visitors to GF Machining Solutions’ stand at EMO Hannover 2019 discovered how SMART wire equipped with radio frequency identification (RFID) chips can help them realize the full potential of their AgieCharmilles CUT P series wire-cutting Electrical Discharge Machining (EDM) solutions and achieve Industry 4.0-level process control.

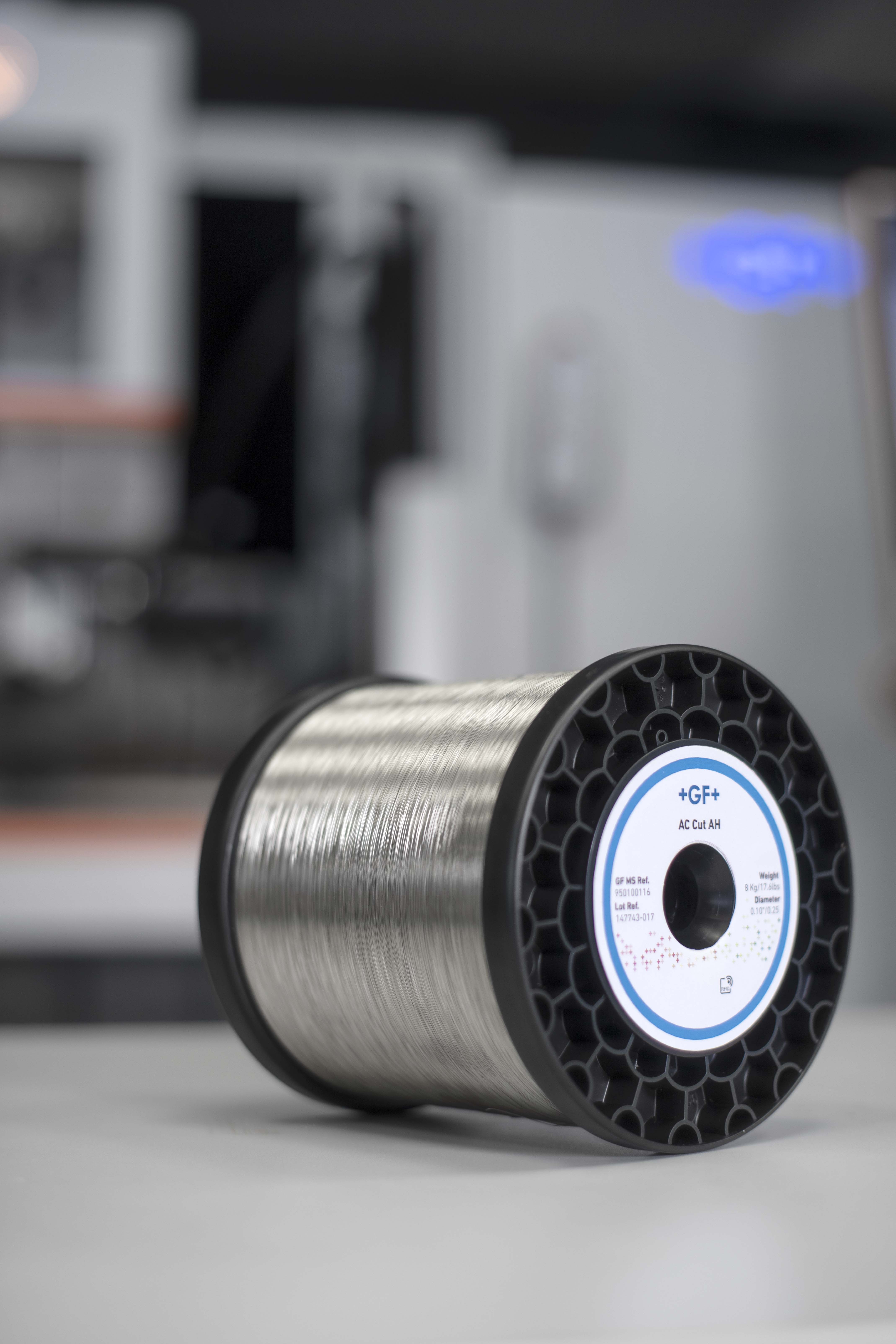

As manufacturers look for ways to exploit the full potential of their equipment and achieve greater process control, GF Machining Solutions Customer Services is connected to their needs with SMART wire. All of Customer Services’ premium wires are equipped with RFID chips, so users benefit from greater process continuity and traceability as well as appreciable process enhancement. That means manufacturers can use their CUT P machines to their full potential and achieve Industry 4.0-level process control.

Process continuity

Thanks to SMART wire’s monitoring capabilities, the machine operator always knows how much wire is available for the current job. The moment a spool of SMART wire is installed, the CUT P machine recognizes the wire length. So, the user knows by a glance at the wire spool status whether there is enough wire on the spool to complete the cutting operation without interruption.

Process traceability

At the same time, wire traceability is enhanced by the wire data, including date of manufacture, type, lot and expiration date, in the machine report. That advanced traceability is especially important in wire-cutting EDM applications for risk-averse sectors like aerospace and medtech.

Process enhancement

SMART wire users can machine with confidence that they are using the right wire for the job, because SMART wire checks the wire technology selected on the machine and optimizes the machine performance accordingly.

A SMART wire for every need

Always connected to customers’ needs, GF Machining Solutions Customer Services offers a wide range of SMART wires to help improve process continuity and traceability and optimize machine performance. For example, if the machining priority is surface quality, AC Cut AH 900/500/400 and AC Cut A 900/500 SMART wires are available. To achieve best productivity,

AC Cut VS 900+, AC Cut VS 900/500 and AC Cut D 500 SMART wires are available. Users’ cutting speed is the top priority with AC Cut VH SMART wire, and AC Brass 900/500/400 is a multipurpose SMART wire.

www.georgfischer.com