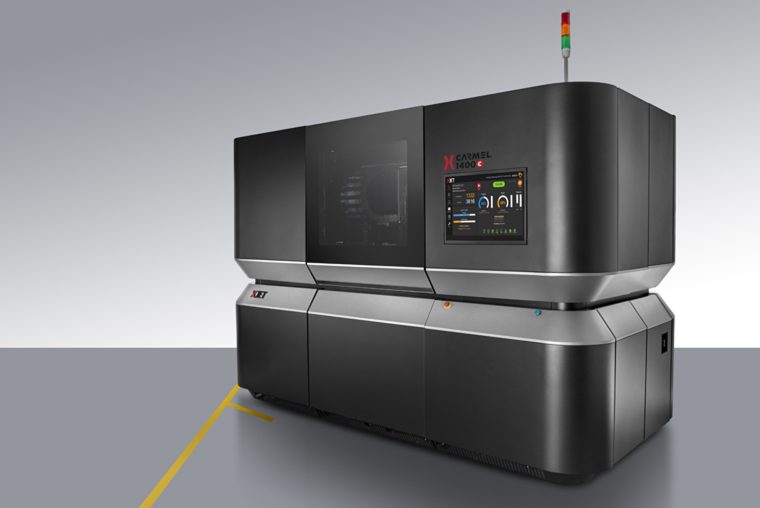

The Carmel AM system will enable production of premium quality end-use parts with complex geometries

The Carmel AM system will enable production of premium quality end-use parts with complex geometries

XJet Ltd. has announced today that the Manufacturing Technology Centre (MTC), will add XJet NanoParticle Jetting™ technology to its portfolio of additive manufacturing (AM) technologies at its facility in Coventry, UK. Determined that the global coronavirus pandemic will not slow progress, the Carmel system has been shipped to MTC and is scheduled to go live in the coming few months.

Established in 2010, the MTC is an independent research and technology organisation (RTO) that provides integrated manufacturing system solutions for customers large and small across a diverse range of sectors. The MTC hosts the National Centre for Additive Manufacturing (NCAM) which accelerates the adoption of AM by developing the technology and systems required to industrialise AM. Ceramic AM is a key focus area for the NCAM, with the recently published whitepaper highlighting a route to widespread adoption for the UK.

According to Dr Tom Wasley, MTC Senior Research Engineer, XJet successfully demonstrated the ability of the Carmel 1400C in producing premium end-use ceramic parts and scaling up for production, thus making the machine an ideal addition to its existing AM capability.

Wasley explains, “XJet’s NanoParticle Jetting technology delivers very high-density parts, so users can have confidence in the materials. Designers often feel the need to ‘overengineer’ AM parts for basic applications, for instance using thicker walls so parts are less fragile, because they are using AM materials, not the real thing, but this is not the case with XJet. In addition, the large build platform, the lack of interaction with powders and no extra step needed for debinding, scaling up for volume production is easily achievable with minimal time and labour.”

Quizzed on the capabilities of the new XJet system, Wasley says, “The surface finish that can be achieved with XJet is arguably very hard to replicate with any other kind of additive process. It also provides a means to make small, intricate and extremely detailed parts.”

MTC’s Carmel 1400C system will enable the manufacture of ceramic parts that are highly complex. Components will feature superfine details, smooth surfaces and pinpoint accuracy – making the promise of zero-cost complexity a reality.

Wasley goes on to affirm the real market need for these kind of parts, stating, “There is a high demand for parts like this in the aerospace, medical, dental and defence industries, some businesses are interested in high precision tooling, but largely they’re looking for end-use parts. We’ve been working in ceramics for over six years, and now we’re looking forward to growing our in-house AM capability. A lot of the organizations that are interested in ceramic manufacturing are searching for a means to batch produce custom, personalized products and the volume capability of the XJet printer will help to realize this need.”

XJet CBO, Dror Danai, states, “We develop our technology so companies can easily move from one design to another, at any point in the manufacturing process, with true freedom of design and zero-cost complexity. However, it’s organisations like MTC that will push the technology to its limits and see what it can really do, make possible what was previously impossible. We’re very excited to work together and see how MTC applies the technology.”

www.xjet3d.com