3M Korea selected PolyJet technology to produce prototypes with multiple materials.

3M Korea selected PolyJet technology to produce prototypes with multiple materials.

3M serves customers through six business segments, producing some of the world's best-known consumer brands, such as Scotch, Post-it and Scotch-Brite. The 3M Korea branch produces a wide range of household and electronic products.

Founded in 1970, Swany Company Ltd., located in Nagano, Japan, initially prospered as a small manufacturing company building micro-motors for electrical appliances. But in the 1990s, when major manufacturers began moving their facilities to more cost-competitive locations in Asia, Swany's business declined steeply.

Founded in 1970, Swany Company Ltd., located in Nagano, Japan, initially prospered as a small manufacturing company building micro-motors for electrical appliances. But in the 1990s, when major manufacturers began moving their facilities to more cost-competitive locations in Asia, Swany's business declined steeply. This functional nylon impeller prototype (black) works for long test cycles.

This functional nylon impeller prototype (black) works for long test cycles. Founded in 1904, Thermos Company is an icon in insulated food and beverage containers. Along with its venerable coffee vessels, Thermos manufactures children's lunch boxes and other consumer products. The household name continues to innovate, building on its impressive list of firsts that includes vacuum-insulated food jars and personal bottles, and ultra-portable titanium bottles.

Founded in 1904, Thermos Company is an icon in insulated food and beverage containers. Along with its venerable coffee vessels, Thermos manufactures children's lunch boxes and other consumer products. The household name continues to innovate, building on its impressive list of firsts that includes vacuum-insulated food jars and personal bottles, and ultra-portable titanium bottles. Let's use our light resources efficiently!

Let's use our light resources efficiently! Utilizing Stratasys' PolyJet technology, Unilever 3D prints injection mold tools to create prototype parts in final material, for full functional and consumer testing

Utilizing Stratasys' PolyJet technology, Unilever 3D prints injection mold tools to create prototype parts in final material, for full functional and consumer testing Due to new technologies like 3D printing, rapid prototype manufacturing becomes the standard throughout different industries. When it comes to prototyping optical elements, mostly smaller quantities are required. Until the uprise of the 3D printer only manufacturing methods that were more suitable for larger volume production were available in most industries.

Due to new technologies like 3D printing, rapid prototype manufacturing becomes the standard throughout different industries. When it comes to prototyping optical elements, mostly smaller quantities are required. Until the uprise of the 3D printer only manufacturing methods that were more suitable for larger volume production were available in most industries. Over the past years precision polymer optics have improved rapidly. This material evolution shows in the capabilities of polymer optics. At LUXeXceL we use an unique type of UV cured PMMA. Other companies might use injection molded plastic optics. Precision polymer optics are used in different industries. In this blogpost you will learn more about the applications that are fit for polymer optics.

Over the past years precision polymer optics have improved rapidly. This material evolution shows in the capabilities of polymer optics. At LUXeXceL we use an unique type of UV cured PMMA. Other companies might use injection molded plastic optics. Precision polymer optics are used in different industries. In this blogpost you will learn more about the applications that are fit for polymer optics. 3D printing is extremely popular these days. Everyday new products, which are printed, are presented throughout different industries. From a table in your house to customized clothing, almost everything can be 3D printed. With this 3rd manufacturing revolution, 3D printing applications for business to business markets arise.

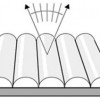

3D printing is extremely popular these days. Everyday new products, which are printed, are presented throughout different industries. From a table in your house to customized clothing, almost everything can be 3D printed. With this 3rd manufacturing revolution, 3D printing applications for business to business markets arise. With lenticular printing it becomes possible to present a 3D effect on a flat surface. The concept is based on the use of many lined lenses. These lenses diffract the light in different angles, for our left and right eyes. When one image is seen with the left eye and another image can be seen with the right eye a lenticular 3D effect is created. In this blogpost we will tell more about lenticular effects and how there are used in optics.

With lenticular printing it becomes possible to present a 3D effect on a flat surface. The concept is based on the use of many lined lenses. These lenses diffract the light in different angles, for our left and right eyes. When one image is seen with the left eye and another image can be seen with the right eye a lenticular 3D effect is created. In this blogpost we will tell more about lenticular effects and how there are used in optics. We developed an unique 3D printing service for products that demand a high standard in transparency, like optics. Our Printoptical© Technology enables us to create optical components, like micro structures, fresnel lenses or freeform lenses. Our custom 3D printing process offers full design freedom and endless new possibilities. In this blogpost we will dive deeper into the capabilities of our 3D printer and our 3D printing process.

We developed an unique 3D printing service for products that demand a high standard in transparency, like optics. Our Printoptical© Technology enables us to create optical components, like micro structures, fresnel lenses or freeform lenses. Our custom 3D printing process offers full design freedom and endless new possibilities. In this blogpost we will dive deeper into the capabilities of our 3D printer and our 3D printing process.