Fast & reliable production of cell-culture device for IVF with new material and NanoOne-printer

Fast & reliable production of cell-culture device for IVF with new material and NanoOne-printer

A novel material for 2PP 3D-printing will contribute to a game changing innovation in the in vitro fertilization (IVF) market. UpFlow, a photopolymerizing material developed by UpNano GmbH (Austria), allows the fast and precise 3D-printing of micro-environments for a novel type of dynamic cell culture.

Developed by IVF-specialist Fertilis Pty Ltd (Australia), this offers a better controlled and less variable environment for embryos before implantation and mimics the human body closer than other products currently on the market. Together with a NanoOne 2PP 3D-printer by UpNano, this allows for a 30 – 40% reduction of implantation cycles as commonly required to get pregnant, thus saving patients’ emotional and financial pain.

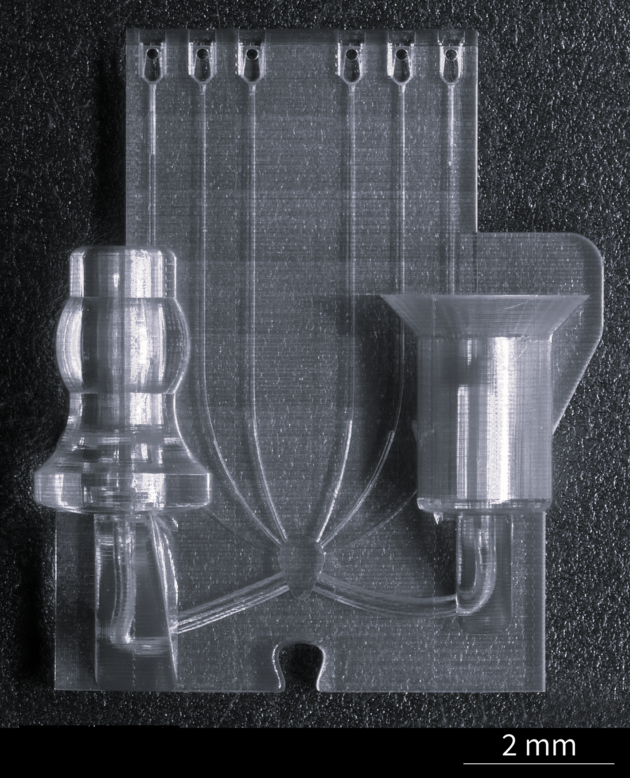

In vitro fertilization (IVF) is a stressful time. Not only for parents, but for embryos, too. Keeping them safe and well requires exposure to repeatedly changing conditions during the pre-implantation phase. Not only does this cause significant stress, but it also increases the risk of failure, making repeated IVF cycles necessary. Therefore, in order to reduce stress to the embryo and increase success rates of IVF, Fertilis developed and patented a unique environment for the critical life phase between fertilization and implantation of the embryo. This first-of-its-kind 3D-printed micro-device incorporates features 0.05mm in diameter and allows to precisely monitor and control the culturing process of the fertilized egg, eliminating the need for IVF-practitioners to move cells between petri-dishes.

GO WITH THE FLOW

And it is exactly those minuscule features – channels with a diameter smaller than a human hair – that proved challenging in the production – especially with material and printers from other manufacturers. Denise Hirner, Chief Operating Officer and co-founder of UpNano, explains the advantage of the company’s latest addition to its material portfolio: “UpFlow offers a lower viscosity than any other 2PP-material with comparable biocompatibility. This allows for a far superior post-production processing, especially the flushing of the very fine channels in order to remove unpolymerized material and ensure reproducibility of structural elements..” UpNano achieved this by choosing specific base resins for the UpFlow material that keep the viscosity of the material low until a final UV-exposure hardens the material and makes it ready to use. Other advantages of the material include a high optical transparency – making it ideally suited for microscopic inspections of the incubated embryos – and a very low autofluorescence.

Fertilis uses UpFlow with a NanoOne-printer recently delivered to the Australian National Fabrication Facility (ANFF) at the University of South Australia. This printer not only improves the quality of the 3D-printed micro-device for incubating embryos, but also the speed of production as Marty Guavin, CEO of Fertilis, explains: “Previously, the 3D-printing of our microfluidic devices took a full fortnight. Now 4h only. That is an exceptional acceleration of the production process. And, best of it all, using UpFlow results in a better-quality product than achieved before.”

But it is not there that the improvement of the production process stops. Using a NanoOne also allows to take full advantage of its adaptive resolution technology. This can modulate the focus width of the laser beam whilst printing. By this, larger and smaller features can be printed in one go, increasing production time and quality. Denise Hirner extends: “The microfluidic device of Fertilis have minute channels as well as larger structures to connect the device to tubes necessary for the incubation process. Being able to print across a range of scales –from nanometers to centimeters – the NanoOne can print this all in a single production cycle.” This greatly enhances the tight fitting of the connectors to the tubes and reduces the risk of any leakage.

Taken together, microfluidic devices manufactured using UpFlow on a NanoOne printer protect the embryo and enable automated changes of the nutrient medium that surrounds the embryo. This provides the most optimized growth environment ever developed for IVF. Marty Guavin adds: “Our device allows fertilization, embryo culture and embryo cryopreservation to occur in the one structure – no more moving embryos around by hand. This, in fact, increases the success rate significantly and reduces time, costs and stress for the parents.” For UpNano, the development of UpFlow demonstrates once more the enormous potential of 2PP 3D-printing for cell and medical research. This has also been shown by UpNano with introducing X Hydrobio INX© U200, the only commercially available resin that allows embedding living cells straight from a culture plate within highly precise 3D-printed structures for biological applications.