The preliminary World Robotics data for China released by the International Federation of Robotics (IFR) shows a sales increase of industrial robots by 19% in 2020.

The preliminary World Robotics data for China released by the International Federation of Robotics (IFR) shows a sales increase of industrial robots by 19% in 2020.

“The outlook for the robotics industry is optimistic”, says Milton Guerry, President of the International Federation of Robotics. “In China, where the coronavirus lockdown came into force first, the robotics industry started to recover already in 2020. In total 167,000 industrial robots were shipped.”

Market growth in China also has a strong positive impact on foreign suppliers – up 24% or 123,000 industrial robots were shipped from abroad. Japanese suppliers have a dominant market share. Domestic suppliers delivered 44,000 units to their home market which is an increase of 8% compared to 2019.

Worldwide, North America and Europe

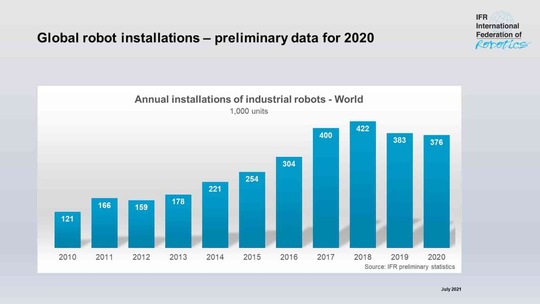

Global robot installations in 2020 were down 2%, particularly under the impact of the Corona pandemic. Still the decline in sales was more moderate than expected.

OECD projects global GDP growth to be 5.5% in 2021 and 4% in 2022. Nevertheless, the situation is mixed in different countries.

The order intakes of the robotics industry 2021 give reason to expect strong growth in North America and Europe. Order books in the US for example are filling up fast. In Germany, the forecast for the current year shows a strong recovery and signifies a positive turning point for the industry. Even better sales figures will be achievable if the current supply bottlenecks for key components can be quickly overcome.

Reduction of carbon footprint

The global path to climate neutrality is generating new business. In order to achieve the ambitious climate targets, economies have started to scale renewable energies and environmental technologies to unprecedented dimensions. Robotics and automation enable companies of all sizes to produce the components needed, e.g. fuel cells for hydrogen-powered cars or batteries in the transport sector and solar panels in the energy sector. The new generation of easy-to-use robotics helps to optimize performance in the production process and move manufacturing closer to regional markets at competitive cost.

“Robotics have proven flexibility to quickly adapt production and respond to changes in demand as well as smaller batch sizes,” says Milton Guerry. “The benefits of increased productivity safeguards jobs by keeping companies competitive.”

www.ifr.org