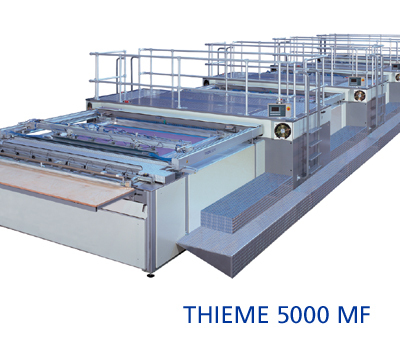

THIEME GmbH & Co. KG, the leading manufacturer of screen printing machines, with headquarters in Teningen, Germany, has developed a new generation of screen printing multi-colour lines. The series THIEME 5000 L, which is based on the proven THIEME multi-colour technology, offers the user the highest printing performance.

THIEME GmbH & Co. KG, the leading manufacturer of screen printing machines, with headquarters in Teningen, Germany, has developed a new generation of screen printing multi-colour lines. The series THIEME 5000 L, which is based on the proven THIEME multi-colour technology, offers the user the highest printing performance.

The THIEME 5000 L for the printing formats 1,600 mm x 2,100 and 1,600 mm x 2,600 mm and is available in the UK and Ireland from THIEME KPX.

„We have put a considerable effort into the research and development," reports Peter Geiger, technical director at Thieme. „Both the basic construction of the machine as well as various technical components were reworked and improved in many ways."

Short set-up times thanks to intelligent functions

The users of the new machine series will be pleased by the various innovations made to improve productivity. For example, the machine automatically adapts to various sheet formats and materials. On one hand the vacuum zones of the printing table, which keep the sheet completely flat, are automatically adapted to the sheet format.

The standard design of the THIEME 5000 L offers three vacuum zones which can be switched on and off; a multi-vacuum table is available with up to 48 zones depending on machine model. The operator inputs the sheet format into the operating panel, and the system automatically activates the corresponding vacuum zones and respectively deactivates the zones which are not required. For smaller formats, this eliminates the time-consuming masking of the print tables.

The positioning of the media in registration has been simplified by means of a lay guide which works on both sides (for double-sided work). The sheet is automatically fed towards the leading edge stop blocks where its correct position is then verified via optical sensors. The front lay guides with the fiber optic sensors are easily located by the operator in the proper position, varying according to the substrate format. Driven by a servo-motor, the vacuum lay guide assumes a position, to the left or right, to correspond with the programmed sheet width. Manual intervention is eliminated.

Simple operation and optimum printing process thanks to modern touchscreen SPC control system

Like its „big sister" series the THIEME 5000 XL range, the machines in the

THIEME 5000 L series come equipped as standard with a modern touchscreen SPC control system. Each printing station is equipped with a master control unit, which can be used to control all the line functions; safety-relevant functions are each controlled within individual printing stations. Its streamlined programming which focuses on optimizing operational functions, makes the machine very operator-friendly. Taking into account different materials and printing tasks, job data can be stored and called up again as required, considerably shortening set-up ties. An error diagnostic system, which was the subject of thorough research and development, enables the speedy correction of errors and operational faults.

Fast remote maintenance using broad band Internet connection

A new remote maintenance system via VPN (Virtual Private Network) is being used for the first time for THIEME 5000 L. The system enables faster error diagnosis than ever before with the aim of resolving problems remotely without the need for a technician on site. The new diagnostic system is faster because of the higher data transmission rate of the broad band Internet connection compared to the modem previously used. It is also more secure.

Peter Geiger emphasises: „On the one hand, the new system offers comprehensive data analysis and faster software updates. On the other hand, the risk of unauthorised data access and the infiltration of infected software, which can lead to machine faults and production downtimes, are greatly minimised." In addition the cost of an extra telephone line for the modem is eliminated.

Energy saving when drying with new electronic ballast

The new machines are also more energy efficient. With the optional replacement of the transformer on the UV dryer with fully electronic ballast (EVG), the effective power consumption can be reduced by up to 15 percent and the connection power by up to 30 percent. Additionally, the fully electronic ballast allows for a fast and smooth setting of the UV radiant power. The set power is also held constant during network power fluctuations.

M, L, or XL – the right machine for every format

With the introduction of the new series THIEME 5000 L the current product range of the THIEME multi-colour lines appears as follows:

• THIEME 5000 M: Multi-colour line for sheet formats of 750 mm x 1,050 mm up to 1,400 mm x 1,800 mm, output up to 2,200 m2 per hour

• THIEME 5000 L: Multi-colour line for sheet formats of 1,600 mm x 2,100 mm up to 1,600 mm x 2,600 mm, output up to 2,600 m2 per hour

• THIEME 5000 XL: Multi-colour line for sheet formats of 1,600 mm x 3,050 mm up to 2,000 mm x 3,300 mm, output up to 3,300 m2 per hour