Ist-Metz invited the printing industry to Nürtingen, the company's headquarters, and more than 1,300 guests from 46 countries followed the call. In addition to the manufacturer of UV, LED and Eximer curing systems, 55 exhibitors presented their solutions for cost-efficient, high-quality production, from prepress to the final product. By Sabine Slaughter

Ist-Metz invited the printing industry to Nürtingen, the company's headquarters, and more than 1,300 guests from 46 countries followed the call. In addition to the manufacturer of UV, LED and Eximer curing systems, 55 exhibitors presented their solutions for cost-efficient, high-quality production, from prepress to the final product. By Sabine Slaughter

Under the motto "Tradition meets modernity", the organizer demonstrated various applications, including an espresso bar, the X-Press-U, where visitors could choose their espresso according to their character. Ist-Metz developed the refined packaging sleeve for the coffee capsules, which was produced using sheet-fed offset printing with LEDcure technology. Depending on the flavour, the offline finishing was carried out with UV screen printing with golden polyester glitter, high-viscosity and glossy UV relief varnish or laser treatment of motif elements and basic shape. The flexible praline foil packaging contained in the packaging was produced in cooperation with the DFTA flexographic printing association on an 8-colour Bobst flexographic printing machine with central cylinder. In pad printing, the coffee capsules were printed with the slogans of the individual persona "Be Fair", "Be Venturous" and "Be Cosmopolitan". Food packaging

Food packaging

Food packaging was one of the main areas of interest and here, too, Ist Metz stood out with its UV technology. The "SIMPL Dining" lunch box, produced in an environmentally friendly way from renewable raw materials and recyclable, was printed and finished with low migration inks and varnishes. The SIMPL concept was adopted by the catering company and implemented for the first time at the UV Days. The menus can thus be stowed away in former aircraft trolleys to save space. The lid has a sliding function that not only allows a view of the food to be distributed, but also satisfies hygiene requirements. Both the lunch box and the buffet box were produced on a Heidelberg Speedmaster CD102-7 LX five-color UV press and finished with UV coating. The lunchbox was then die-cut and the feeder and holder for the jars were also produced.

All in one

The PadBook offers a mobile and space-saving workplace as an integrated concept with a fold-out folder and holders for writing pads, business cards, pens as well as storage space for tablet accessories with magnetic closure. Folding the PadBook creates a tablet position. This results in fine structures created on a Heidelberg Speedmaster, with two layers of black, magenta and yellow interdeck dryers, followed by silver and effect coating with interdeck dryers. A microstructure is also embossed in the last printing unit, which is then applied and dried in the flexographic printing unit with a final gloss coating. Excimer technology for matting effects

Excimer technology for matting effects

Metz also presented its new excimer laboratory system, which can be used to carry out customer-specific tests to determine optimum parameters. It is equipped with three excimer units which, due to their short wavelength emission, have a low penetration depth and can thus be used for matting paints. At the surface, a thin layer of varnish hardens quickly and contracts over the liquid substrate. Subsequent UV or LED drying ensures that the finely folded surface is preserved. Surfaces produced in this way are highly resistant to chemicals, scratches and abrasion. As an option, an infrared module can be used to preheat and adjust the paint viscosity. Material thicknesses of up to 50 millimeters can be processed at a speed of up to 200 meters per minute. Applications such as the finishing of wood decors and materials, the cleaning and modification of surfaces in display and touch panel production or the matting of web-shaped plastics and foils are possible applications. Shipping packaging

Shipping packaging

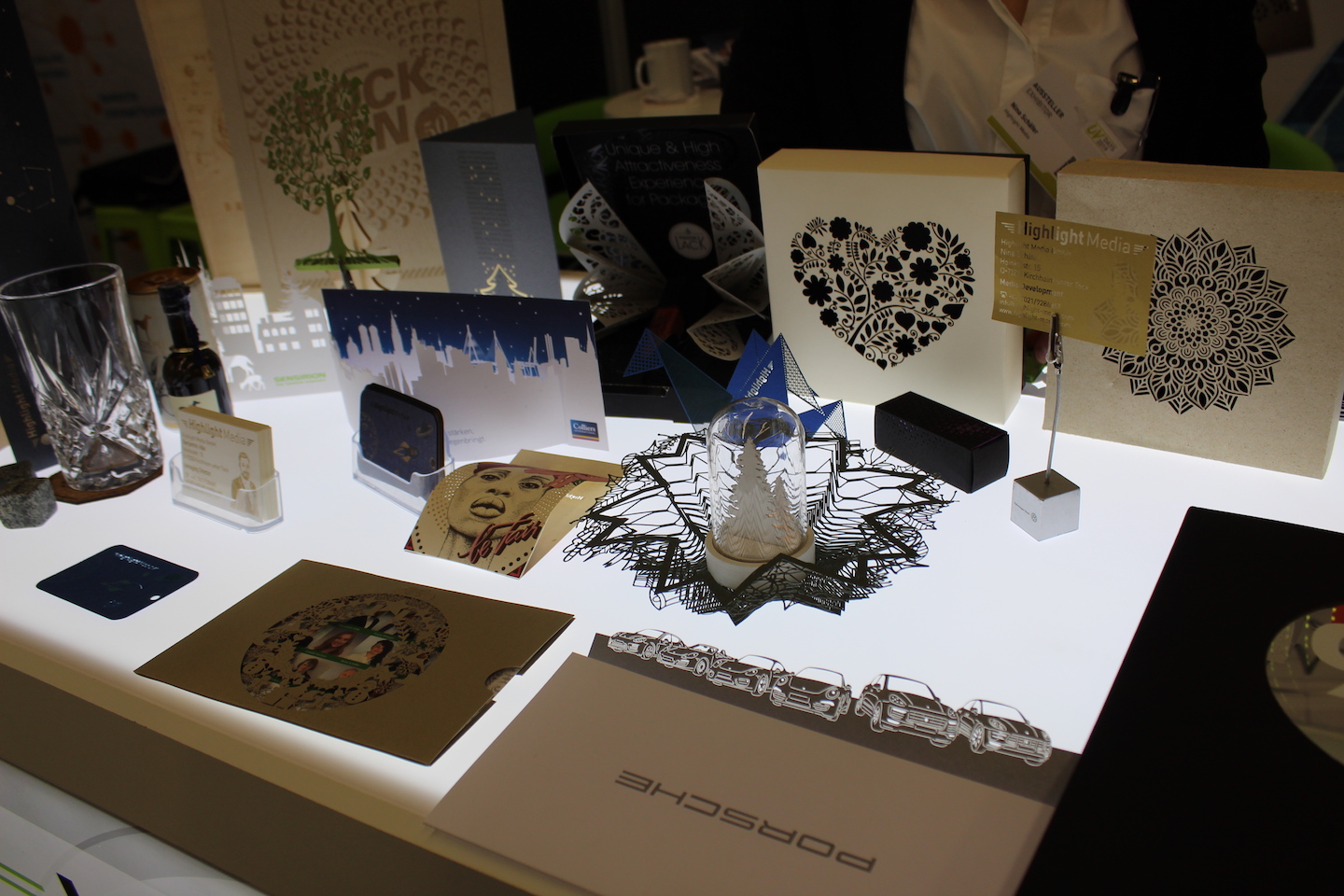

The PrintCity stand featured shipping packaging as well as various types of packaging. Here, too, the trend is towards refined packaging. These increase the buyer's unpacking experience and open up new possibilities in direct marketing. A wide variety of finishing techniques in combination with the production of small batches, individualisation and personalisation can increase the success of the product. One trend here is to simply design the outside of the shipping packaging while presenting high-quality finishing on the inside. Thus only the buyer can see and enjoy this refinement, while the transporter sees only the simple outside without reference to the contents. Thus marketing and selling of high-quality production are strengthened over on-line trade and a positive Auspackerlebnis with the