The grey and windy weather in Lucerne could not stop anyone from visiting the Hunkeler Innovationdays, the trade fair for digital printing. With hundreds of professionals and dozens of companies and organisations, the show was held. The Doxnet on site was one of the attractive conferences. By Sabine Slaughter and Amin Schierenberg.

The grey and windy weather in Lucerne could not stop anyone from visiting the Hunkeler Innovationdays, the trade fair for digital printing. With hundreds of professionals and dozens of companies and organisations, the show was held. The Doxnet on site was one of the attractive conferences. By Sabine Slaughter and Amin Schierenberg.

Doxnet, which celebrates its 25th anniversary this year, was held in combination with the Hunkeler Innovationdays, and there were over one thousand pre-registrations for the Doxnet conference. Right at the start, the organisers announced that Doxnet was being held locally in Switzerland for the ninth time in Lucerne, making it particularly important for entrepreneurs to network with each other.

In various presentations at Doxnet on site, different members and member companies in document management and digital printing presented their concept as well as their new innovations. The day's programme ran from 1:30 p.m. to 6:30 p.m. and began with an opening of Doxnet by CEO Udo Schäfer.

Ricoh

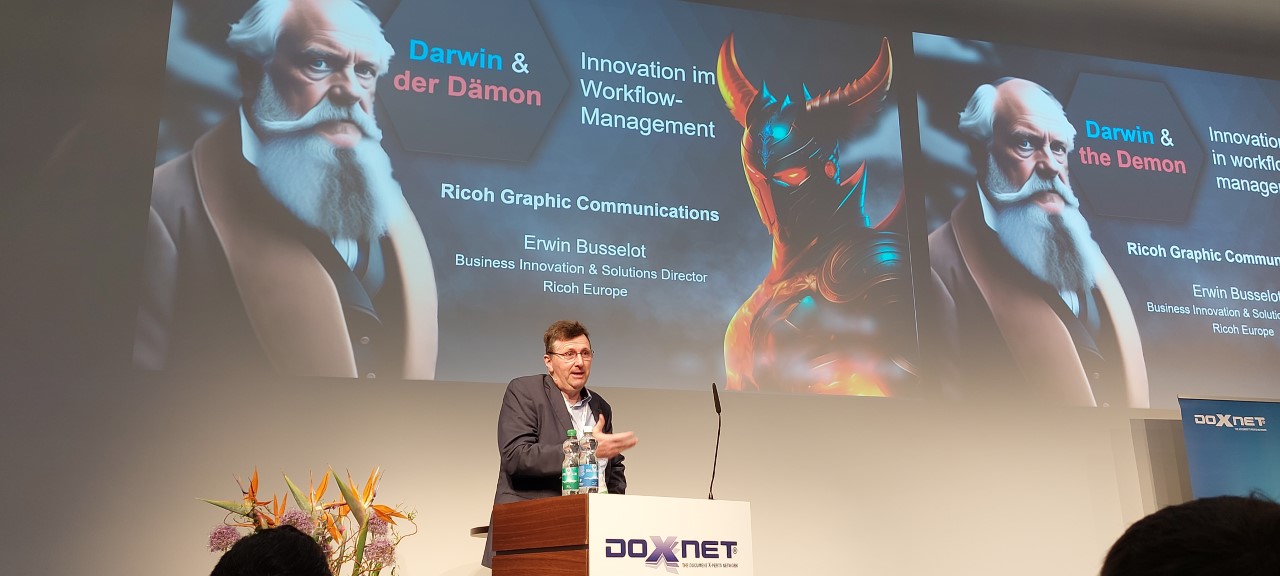

After the introduction of Doxnet, the Ricoh company started a presentation on workflow management, called: "Darwin and the Demon." This was about the advantages of automation. Among other things, one can see more statistics, the current production, error messages, progress, status of the job and much more. The option of cross-site solutions was also mentioned. This means that as soon as the production of the first part is finished, the next location is notified and the order can then be completed there.

Erwin Busselot, Director Business Innovation & Solutions, Ricoh Graphic Communications of Ricoh Europe started with the famous words of the British natural scientist Charles Darwin: " It is not the strongest species that survives, nor the most intelligent, but the one that reacts fastest to change!". This would also apply to companies. As in competitive markets, commoditisation often displaces differentiation. Darwinism is at work here too. However, standardisation can be countered by innovation. Everyone can be held back from innovation by the demon of inertia within.

Erwin Busselot continued by quoting the American writer, publisher, artist and philosopher Elbert Hubbart: "The reason people resist progress is not that they hate progress, but that they love inertia." Those who do not innovate, he said, cannot differentiate themselves. Profits and revenues must adapt and evolve. To continue to generate attractive returns, commercial printers would need to change their core competencies over time, including engaging their employees and educating them about the goals.

Efforts to refocus may be thwarted by the inertia that success creates. Companies that want to innovate often have a poor success rate because they lose the ability to innovate or tie up scarce resources in non-differentiating processes. This is where the demon of inertia would be at work. Integrated technologies, processes and people produce positive results. This powerful combination can help defeat the demon.

For example, workflow management that centralises functions and consolidates legacy processes into a shared services model can free up resources to perform duplicate tasks. Commercial printers could also standardise, simplify and automate or outsource processes.

For example, Ricoh worked with a commercial printer that did not have a clear view of device activity across multiple production sites. The customer felt that all of its production printers were busy around the clock. There was no quick overview of peaks and troughs in production or an assessment of hardware investments to increase capacity. In addition, there was no comprehensive data on which to base tactical and strategic decisions.

After examining how it could make critical improvements, the company implemented RICOH Supervisor. Comprehensive reports and analysis of all production print activities were quickly produced, as well as a clear overview of all equipment usage and productivity. Data analysis showed that no hardware investment was required. In addition, unproductive on-call time was identified, leading to process improvements and better utilisation of the high-speed inkjet printers, resulting in a 20 per cent increase in capacity.

Commercial printers could also improve efficiency and control across all sites with RICOH ProcessDirector. They could replace the inability to respond to capacity bottlenecks and unforeseen events with increased reliability thanks to simple capacity and contingency planning. Lack of site interoperability could be addressed with simple redirection of work, either proactively or reactively as events unfold, and tracking the status of all work across all sites in one place. You could also manage duplication of licences and functional processes to consolidate common licences and functions on a single server, says Erwin Busselot.

The brand new RICOH TotalFlow Producer supports commercial printers in their quest for innovation, he added. The vendor-independent, cloud-based solution expands customer access to print service providers. It allows print files to be sent by email, FTP or via a customised portal. Files are automatically checked without operator intervention and can be processed in the cloud before being sent to a hot folder or MIS.

Ricoh's unique business development programme Business Booster EDGE, re-launched at Hunkeler Innovation Days, helps commercial printers keep their business relevant in a rapidly evolving and competitive landscape, he said. It is designed to help commercial printers introduce profitable new services and create new market offerings. It helps develop skills that match capabilities and trains marketing and sales teams on how to sell using a better, value-based model, Erwin Busselot said.

It also shows ways to innovate to generate new revenue, build new business models, increase value for new and existing customers and increase sales potential, he added. By creating new value and a business plan, Ricoh can help commercial printers adapt and grow, he said. Access to experts, training services, tools, a web portal and a community would also be offered.

All this, according to Erwin Busselot, could cover the five production stages of input, management, preparation, production and output. They could help commercial printers address and solve the challenges they face by enabling them to internalise HENKAKU - the Japanese spirit of change.

Kodak

The Kodak presentation followed. The slogan "Flexibility, Efficiency, Scalability" stayed in mind. As you can already tell, it's all about automation. Even not so fast internet is not a knock-out criterion to be able to use the advantages. For example, "on demand production". For this, the company relies on the cloud. The guiding principle was: "It's not the technology that changes people, but the way people use it."

Wesley Vingerhoets from Kodak highlighted the "Five things printers should know about cloud technology". "Cloud technology makes us flexible. It can make us grow fast or shrink again, depending on our needs," he explained. Preconceptions about over the cloud and data security were highlighted by him. Data centres all over the world made cloud computing possible. As any business is only as strong as its weakest link, scalable solutions should be sought in terms of flexibility and cost savings. "The cloud is more secure than on-site storage," stated Wesley Vingerhoets, who also emphasised that the cloud reduces the risk of failures.

If all relevant aspects were taken into account, then the next crucial question would be: Which technology partner is the right cloud provider. "Technology partners are the heartbeat of your business. Make a wise choice," was his advice to the audience.

Hunkeler

Hans Gut and Matthias Annaheim of Hunkeler picked up on the theme of the Hunkeler Innovation Days, "Next Level Automation". "No matter what industry, the challenges are the same everywhere," Annaheim said. He went on to address the need to rethink processes, develop a continuous improvement mentality and embrace new technologies. Change management, for example, needs acceptance and appropriate communication with those affected, he said. "It is not about replacing people with automation." The crucial thing, he said, is to train people so that they can operate the machines. As reasons and challenges for automation, he mentioned customer and employee satisfaction as well as the quality of the processes.

Hans Gut went into various application examples of what Hunkeler understands by the leitmotif Next Level Automation: For example, a digitally fully networked printing centre. "We want to produce products on demand for the customer. This requires networking and systems that talk to each other." Hans Gut presented the individual steps from order to production to delivery, all of which are digitally networked.

It continued with a video by Hunkeler himself on "Next Level Automation". The key point here: automating everything, being able to produce everything on demand, and doing so as efficiently as possible with recycling after the products' service life. Since this is not yet possible to the desired extent, partners and cooperations are needed. Sometimes this would also happen through acquisitions. More and more, artificial intelligence will and should play a role in relieving humans of work, such as automatically changing printer cartridges. Or that the artificial intelligence automatically prints on different types of paper (depending on thickness, or whether with gloss or without).

Xerox

Xerox used its appearance on stage to draw attention to the right ecosystem for digital transformation. It used to be hardware-driven innovation, but now software plays a bigger role and innovation comes out of software. Among other things, because there are so many different mechanisms that are interconnected and need to work together. Nowadays it is no longer enough to be a normal printer.

Here, innovations in the software help not to miss opportunities and to see new possibilities or opportunities in problems. A higher quality also goes hand in hand with this. The most important thing is that an infrastructure is needed.

Matthias Wagner from Xerox further explained how, in his opinion, production printing successes can be accelerated. Xerox had decisively shaped this area with its developments. "Problematic supply chains, high energy prices and a lack of roof-mounted workers are a problem for all companies," said Matthias Wagner. For this reason, he said, every market participant should secure its share of the digital transformation. He presented the four pillars of automation: printing system, workflow, proven infrastructure support and marketing. His conclusion: automation drives transformation.

HP

This was followed by the presentation of Markus Weiss from HP with the topic ""Automation at every step: maximum productivity for inkjet printing. He sees the solutions for the challenges of the time in ways that show an increase in value for digital production printing. From his point of view, it is important to keep the relevance of printed products high in the public eye, Weiss stated in summing up.

He also presented the new products and gave very promising forecasts. For example, explosive growth: market growth over the last ten years would be over six per cent, with HP having 18 per cent CAGR between 2018 and 2022. Since 2012, he said, HP's PageWide Web printed pages have grown 42-fold to 825 billion pages. The market is facing new challenges, Weiss said. These include rising paper costs, labour shortages and rising printing costs. These factors are offset by demands for faster turnaround, higher value print products, relevance and sustainability. The result would be an increase in value for digital production printing, Markus Weiss concludes.

An example of HP's new effectiveness was the printing of postcards: one hundred thousand postcards could be printed (print, cut and coat) by DG3 within three hours, with quality, glossy paper, productivity and automation at the core. This compares to the company's previous offset press, which would have taken 22 hours to complete the job.

Simplification and scaling of online print automation would be a key point. Jobs arrive at the printers through different channels (web portal, storefront, customer request). The production environment with automated prepress, press, finishing and collating would require reporting, tracking and notifications to all parties involved in the production process and reporting. This would be followed by automated dispatch, whereby a connection with the transport company would have to be established, according to Markus Weiss.

The HP PageWide Advantage 2200, which HP presented at the Hunkeler Innovation Days, would fulfil all these points together with the right software packages. For example, with the automatic On Press Profiling (profiling on the press), a time saving of 90 per cent could be achieved in the area of colour accuracy and precision. The optimal Smart Workcell Controller would also help to simplify the printing process.

Canon

"Make it Future Proof with Technology and Business Innovations" was the title of the presentation by Michael Krebs from Canon. He showed ways to achieve sustainable growth. "Nothing works without software," said Krebs. He proudly presented two innovations from Canon, emphasising the importance of smart processes. With a focus on productivity, quality, ease of use and sustainability, the systems deliver the right technology for smart processes: Job processing with minimal intervention by connecting the client and print provider to offer the best service to customers. "New technologies in particular open up opportunities for growth." Krebs described print as the most effective communication channel.

The company believes that technological innovation is related to business innovation, said Michael Krebs. The two would play into each other and depend on each other. For example, automatic book production, increased productivity and a seamless end-to-end process are desired by the customer. With the ColorStream 8160 inkjet web press, Canon would be future-proof. The result would be reduced time from order entry to delivery, 24/7 production for longer runs and offset-like quality with the flexibility of digital printing. This would offer complete production efficiency.

Sport and print

The keynote address was given by Berni Schär, one of Switzerland's most distinctive voices. The sports reporter legend spoke about the top performances in top-class sport and drew parallels for the associated success factors for exhibitors and entrepreneurs which would apply to everyone. It depends on the fire, the passion in a person or company, not to give up and to do better the next time. In other words, learning from mistakes. Especially goal orientation, focus and persistence are important. Just as important, however, are sleep and the prevention of injuries and recovery in top-class sport - these recovery phases can also be transferred to entrepreneurs, manufacturers and all those involved in the digital printing process chain.

The networking event following the presentations was used extensively by the enthusiastic Doxnet members, with the focus on informal exchange.