The annual event, held alternately in Brussels and Chicago, seems to have little to do with the general exhibition fatigue that has gripped the printing industry in relation to traditional major events. After the last PRINT was held in Chicago at the beginning of October, and other trade fairs in recent years have already disappeared from the calendar, the future of Labelexpo, which celebrated its 40th anniversary, is assured. 38,903 visitors and 693 exhibitors found their way to the exhibition halls. By Sabine Slaughter

The annual event, held alternately in Brussels and Chicago, seems to have little to do with the general exhibition fatigue that has gripped the printing industry in relation to traditional major events. After the last PRINT was held in Chicago at the beginning of October, and other trade fairs in recent years have already disappeared from the calendar, the future of Labelexpo, which celebrated its 40th anniversary, is assured. 38,903 visitors and 693 exhibitors found their way to the exhibition halls. By Sabine Slaughter

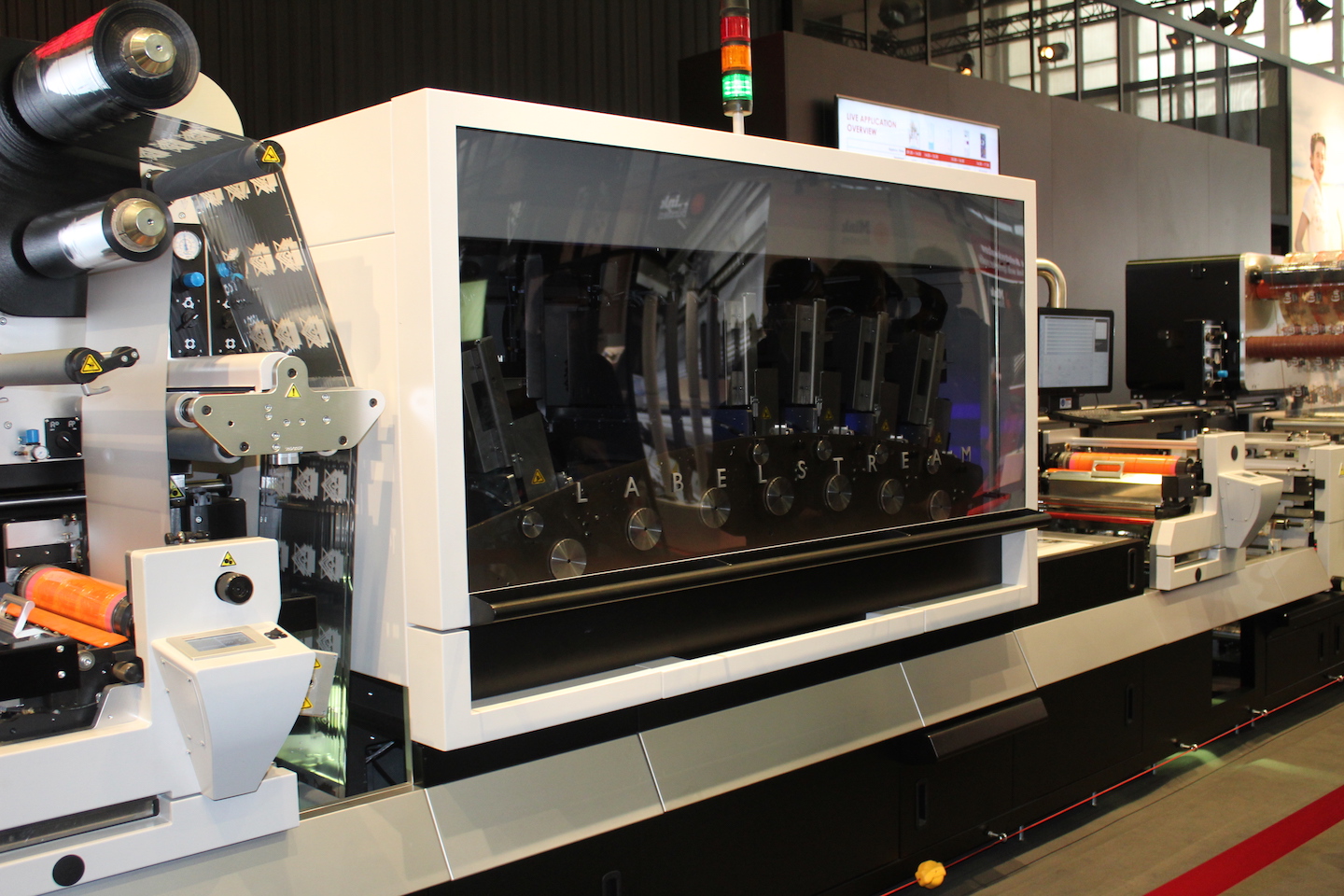

One of the words heard almost everywhere was hybrid printing presses. These are characterized by the fact that they contain digital as well as conventional analog printing units. One advantage is obvious here: labels can be printed in one pass, even personalised or individualised, and a wide variety of printing processes can be implemented depending on the application. And the finishing area is not neglected either. This ensures variety and the possibility to produce even smaller run lengths cost-effectively and efficiently.

In addition to monochrome imprint solutions, which appeared shortly after the turn of the millennium, these have been available since IGAS 2007 at the latest, when a flexo-inkjet combination with over 10 printing units, including four stations for colour inkjet printing, and, among other things, a film unit from Taiyo was presented. Now, a dozen years later, almost every printing press manufacturer has hybrid solutions in its range.

But whether hybrid printing presses are just a trend or a sustainable solution, the future will show. We have collected some of these solutions and looked around at Labelexpo. DigiFlexo and digital printing at Bobst

DigiFlexo and digital printing at Bobst

The Swiss company presented the Master DM5. This incorporates Mouvent's cluster technology for inkjet printing with Fujifilm Dimatix Samba printheads. The latter are easy to change, with fully integrated colour, conditioning and electronic features. The print resolution is 1,200 x 1,200 drops per inch (dpi). Full digital automation of the press means that only one printer is needed to print high value-added label jobs in short and medium runs. Job changes on-the-fly, without stopping the press, are possible for flexo, digital, die-cutting and stripping processes. All analog tools (impression cylinders, die-cutting plates) are changed automatically. Waste disposal is also fully automatic.

Ink-on-Demand (IoD) is an optional extra for DigiFlexo printing units, a revolutionary solution that replaces conventional ink containers with a single rubber tube that delivers 30 grams of ink to the printing unit. The system eliminates ink trays and chambered doctor blades and performs fully automatic washing of the printing unit in less than a minute.

In addition, the press has a full range of value-added features, including coatings, varnishes, tactile effects, 3D effects, hot stamping, cold foil, embossing, die-cutting, die-cutting, screen printing, flexography and digital variable data printing (VDP).

"The Master DM5 is our first fully digitally integrated hybrid press and represents a new era in the production of self-adhesive labels with completely new levels of productivity and economy," said Jean-Pascal Bobst, CEO of BOBST. "BOBST can now offer the full range of digital, hybrid and DigiFlexo solutions that are perfectly integrated, interchangeable and scalable to meet all current and future requirements".

Other innovations on the stand included the LB802-WB six-colour digital label press which uses 100% water-based mouvent inks. This eliminates the emission of VOCs, which according to the company ensures indirect food compliance. The wide range of applications, from self-adhesive to wet-glue substrates, including structured natural papers, is underlined by a machine speed of 100 metres/minute. The UV version LB701-UV from Mouvent can print six-colour plus white, has a print resolution of 1200 x 1200 drops per inch (dpi) just like its sister and also prints on both metallised and transparent material.

The UV version LB701-UV from Mouvent can print six-colour plus white, has a print resolution of 1200 x 1200 drops per inch (dpi) just like its sister and also prints on both metallised and transparent material.

The Vision M1X Inline UV configuration machine offers a web width of 370 millimetres. Designed with automation and connectivity in mind, the press can print and convert a variety of applications in a single pass.

A combination of inline UV flexo, REVO digital flexo and the V-Flower printing unit, which enables job changeovers within one minute "on-the-fly" without stopping the press and at 95 percent running speed, was demonstrated with the Master M6. On the stand, it was equipped with the fully automated DigiMount flexo plate mounting system, which Bobst says improves the speed and accuracy of plate mounting.

Digital Pressure Bar

The Heidelberg/Gallus stand featured the hybrid Gallus Labelfire. With a printing speed of up to 70 metres/minute and digital finishing options thanks to the integrated Digital Embellishment Unit (DEU), it combines conventional and digital printing options. According to the company, the newly launched, moveable digital printing bar for digitally printed opaque white and a new rotatlon quick-change die-cutting unit will be particularly effective in narrow-web printing of self-adhesive labels. Here, the DEU can provide tactile relief effects as well as matt or glossy spot varnishing in various thicknesses. The Labelfire exhibited used the low-migration Heidelberg Saphira digital inks recently launched at the show.

The company presented the well-known Gallus Smartfire, an entry-level model for digital label printing that is particularly suitable for short and medium runs.

A ten-colour Gallus Labelmaster Advanced with a new rotary quick-change die-cutting unit was on show. A digital printing bar with a width of 430 millimetres was also implemented, enabling digital white printing with high opacity. According to the company, the press underlined the cost-effective flexographic and screen printing with high process flexibility and finishing options at running speeds of up to 200 metres/minute. Gallus sold its hundredth Labelmaster, which was launched two years ago, during the trade fair. EF Symjet with 430 mm width

EF Symjet with 430 mm width

MPS and Domino presented the hybrid EF Symjet which includes the new Domino N617i printing unit on the EFA Flexo platform. Five flexo stations. Digital cold foiling, short cold foiling for single images and optical effects, lamination and die cutting are further features of the machine, which was presented for the first time in this width, in addition to the digital printing unit specially developed for the EF Symjet.

The new E-sleeve technology ensures predictable printing results in combination with increased speed. "Flexo printing sleeves play a crucial role in the entire flexo printing process, as they have a major impact on print efficiency and quality", says Bert van den Brink, co-founder of MPS. "We at MPS saw the need to move from sleeves using an aero mounting principle with a compressible inner core to a design with precise concentricity across the entire plate for optimum print results. It's a turning point for the printing industry." MPS is one of the most important features of the MPS E-Sleeve optimal print settings to avoid unnecessary bouncing, precise concentricity, constant parallelism for ideal register over the entire print length and increased dimensional accuracy for optimal register between all colours and stencil stations. Conventional analogue printing machine S7

Conventional analogue printing machine S7

Spande came from China as a first-time exhibitor and brought his S7 flexo printing machine with him. Web widths of 370, 450 and 520 millimetres and a printing speed of up to 200 metres/minute can be printed on substrates between 12 and 600 microns. According to the company, the S7 series presses have eight servo motors in each print station, the i-Pressure system that automatically retrieves and loads precise print prints, and the i-Vision intelligent registration and impression system that ensures register corrections at each print station independently and at any time - when starting the press, changing jobs, etc. Intelligent makeready processes, short make-ready times and minimal waste are the benefits for the customer.

Nilpeter celebrated two anniversaries

Not only Labelexpo celebrated a round birthday, Nilpeter did too - and already the hundreds. The FA-17 produced anniversary order ("Nodo d'Amore" with new high build inkjet coatings, high opacity white inkjet and semi-rotary high-speed die-cutting unit. The FA-22 also ran two shrink sleeve applications, protein powder and drinking yoghurt labels, in line with market trends for wider roll-fed label printing with a new 22'' quick-change die-cutting unit. The press was also equipped with coating, lamination, the new quick-change die-cutting unit and UV LED drying.

The world premiere of the new FA-26 also took place at Nilpeter's stand. This machine is designed for flexible packaging and labels with added value for short runs - from pouches and bags to wrap-arounds, shrink sleeves, labels and more.

Digital printing

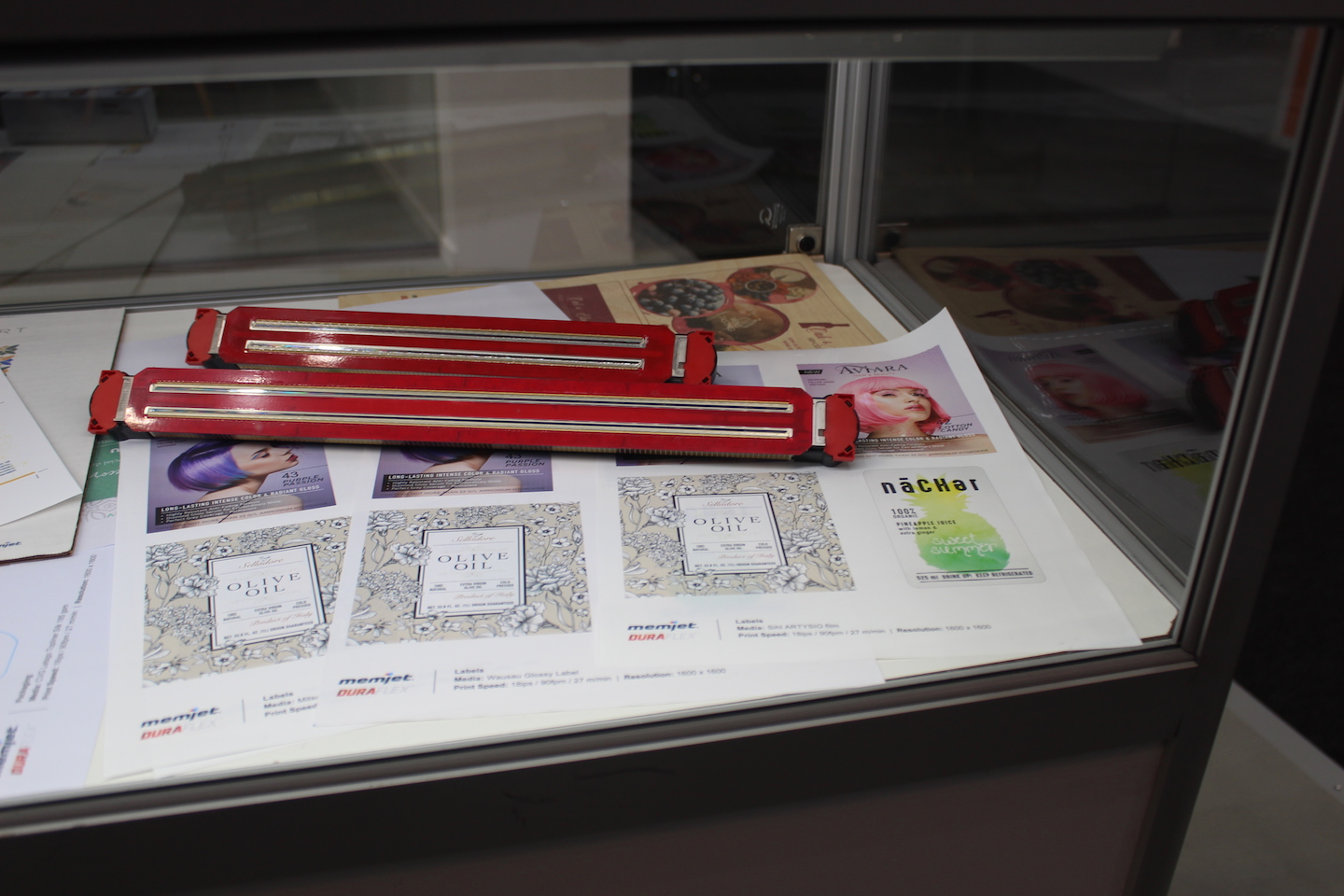

A lot has also happened in the area of digital printing of labels. In addition to a wide variety of substrates, which also brings with it a wide range of applications, this area has proven to be suitable not only for very short but also medium run lengths. Both toner- and inkjet-based solutions offer acceptable speeds, excellent quality and very good register, with cost efficiency, personalization, customization, fast job changes, and time-to-market meeting the needs of brand owners for short-term, event-based, regionalized campaigns. Inkjet and toner in the range

Inkjet and toner in the range

Xeikon is one of the few companies that have both technologies in their program. The production of stand-up pouches was demonstrated on the Xeikon CX500. The dry toner technology offers complete food safety. Xeikon's fleXflow for stand-up pouch production was developed, according to Filip Weymans, vice president of marketing, "to meet the growing consumer trend for mobile food and beverage consumption. Xeikon continues to meet converters' demands for profitable short runs and fast turnarounds, variable data printing in full color and a wide range of applications. Brand owners looking for a variety of containers for their products are attracted by the bags' stability, stackability, weight and sustainability. According to the company, this application is particularly suitable for label manufacturers who want to expand their business activities. "Xeikon's CX500 digital press with Cheetah drying technology delivers superior image quality with CMYK and opaque white at 1200 dpi. In the Flexible Packaging Arena, Xeikon will demonstrate the complete process in which text and graphics are digitally printed onto the thermal laminate, with the outer layer prepared with a series of barriers to build the bag prior to the manufacturing process," Weymans continued.

Smart labels enable digital twins

A new smart label solution developed and implemented by Xeikon in collaboration with UPM Raflatac and Magic Add consists of a cloud-based application that extends the functionality of labels and packaging beyond traditional printing methods. It provides track-and-trace capability for labels and is designed to help brand owners who want to bring labels and packaging online better measure the success of their campaigns and manage the supply chain. Jeroen Van Bauwel, Director of Product Management at Xeikon, said: "Each package is made unique with an image, text, number or code and is ready for scanning with standard applications. There are a number of options, such as QR codes, that allow consumers to track their product throughout its lifecycle. Consumers can trace the origin of their product and every step from there to the consumer. They can check storage conditions during transport and track the product's journey from supplier to retailer. Knowing that their product is authentic gives consumers confidence in the brand. Smart labels have the unique ability to enable manufacturers to continue to interact with their customers, even after the initial purchase has been completed and the product has been taken home". Haptic and textured labels

Haptic and textured labels

Tactile and textured labels were printed on the Panther P3000 inkjet printing machine, made possible by a novel combination of the Xeikon X-800.workflow and the PantherCure UV ink. The new haptic printing process not only improves and enlarges the spectrum of possible applications for the premium market, but also saves time, as no changes to the pre-press files are required. Haptic effects on labels are in particular demand from the beer, beverage and food industries as well as the health and cosmetics sectors. Jeroen Van Bauwel, Director Product Management, says: "The process that creates these tactile and textured layers is embedded in the X-800 workflow of Panther technology. Brand owners and designers specify the structure, shape and form of the design. Upon receipt of the files, the workflow automatically recognizes the design elements and generates the data required to control the print head. This creates the haptic effect on the finished print product". A further innovation is the automatically optimized ink application of the white ink layer which is especially important in the area of transparent substrates.

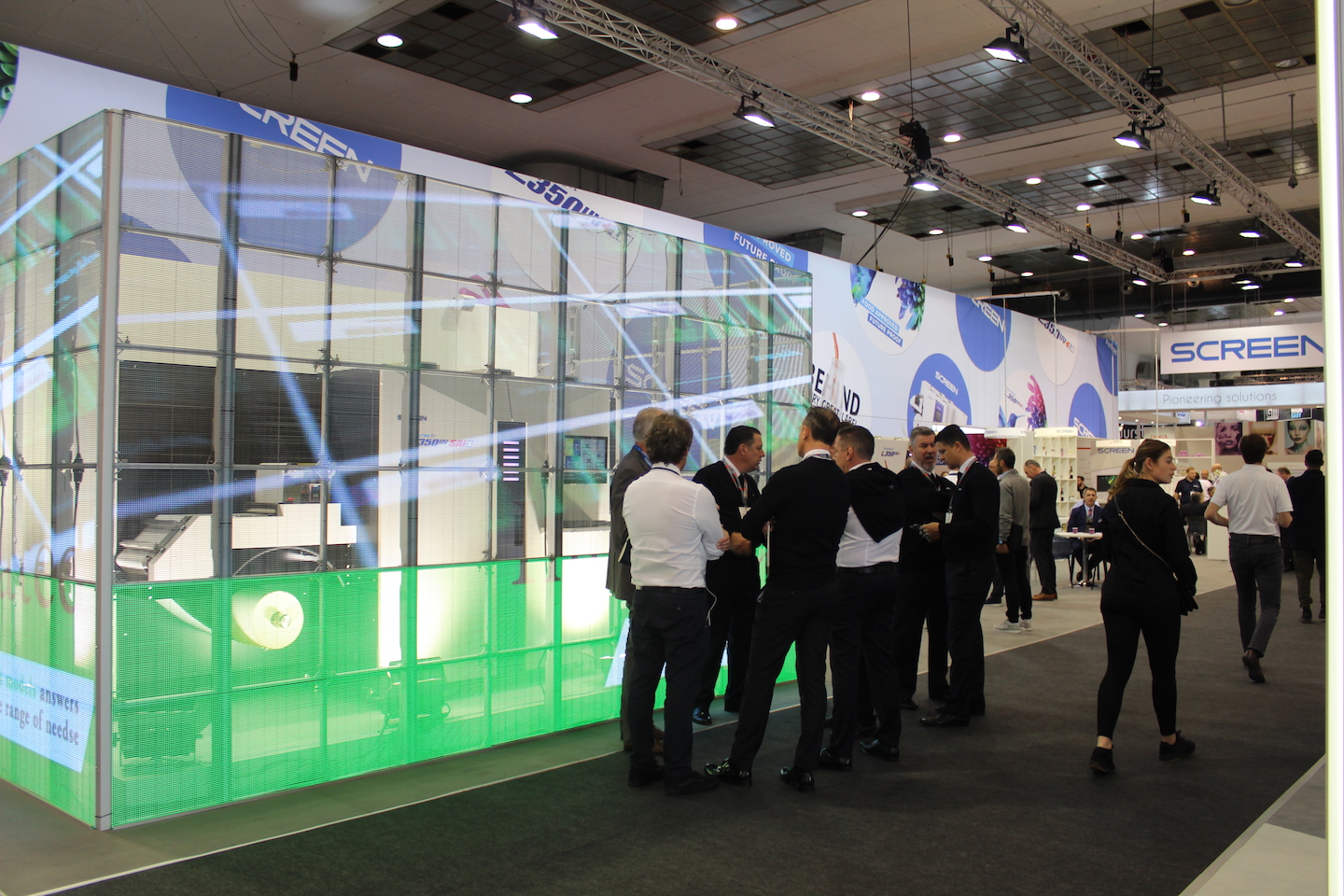

Digital eight-colour printing

The new TruepressJet L350UV SAI series from Screen prints with eight colours. This inkjet-based digital press enables a print speed of 80 metres/minute with CMYKW and optional blue and orange as standard colours. An eighth print head for individual requirements is already provided. The machine is available in four versions - from the entry-level model (E) to the version for printing food packaging labels (LM). A double UV drying unit is also integrated. All machines in this series can be equipped with additional colours on site. The name of the system "SAI" stands for its design concept: extremely "stable" operation, "accurate" colour reproduction and proven "integrated" technologies. In Japanese, "SAI" also means "colour" and "high", expressing Screen's continuous quest for superior colour reproduction. The system also features proprietary color management technologies developed in collaboration with CGS Publishing. These technologies enable far better colour reproduction than was previously possible. Modular production printing press

Modular production printing press

With the TAU RSC platform, Durst has announced new industrial printing presses designed to meet the needs of label and packaging printers. The new Tau RSCi, which was shown together with the current Tau 330 RSC and RSC-E machines, has print widths of 330, 420 or 508 millimeters and a higher print speed of up to 100 meters/minute. New features in the RSC portfolio include a highly transparent white print mode for increased screen-like opacity and a high-speed white mode that enables high-speed printing at 80 meters/minute of all colors, including white, the company said.

Dedicated workflow software for Web2Production and Durst's own prepress software "Workflow Label", which is offered by Durst Professional Services for customizing MIS integration software packages, were presented. New features of the Durst Workflow Label in combination with Durst's customized Smart Shop and integration packages help to meet Industry 4.0 standards and drive the extended Tau RSC portfolio.

Helmuth Munter, Durst's Segment Manager, Labels and Packaging Printing, said: "Labelexpo marks 10 years of Durst in the label industry with a host of new innovations: first with 7 colors, first with chill roller, first with low-migration ink and first with an inert curing system. Launched two years ago, the Tau 330 RSC and Tau 330 RSC E set new standards in label printing and today have more than 50 installations around the world. We are confident that our updated Tau RSC platform will once again lay the foundation for the future of industrial digital inkjet printing in the label industry". Toner and Flexo Printing

Toner and Flexo Printing

Konica Minolta presented the AccurioLabel 230s with a flexo station at its booth, jointly developed with Grafisk Maskinfabrik (GM) for inline white printing. This analogue white printing option can be retrofitted to existing machines. The new toner printing system has been optimized: These include an increase in printing speed up to 23.4 metres/minute, improved productivity, an overprint function, the elimination of the warm-up process, less waste and even more accurate register.

Edoardo Cotichini, Team Manager Industrial Printing at Konica Minolta Business Solutions Europe, explains: "Our AccurioLabel systems bridge the gap between entry-level digital presses and high-end systems. We are therefore expecting great interest from service providers in the label printing sector at the exhibition. We look forward to demonstrating the many benefits of these systems. Above all, they offer user-friendliness and production flexibility, short throughput times and print functions for variable data. We will also be demonstrating our first-class on-site support and service as part of our customer-oriented and partnership-based approach".

Also presented at the booth was MGI JETVarish 2D WEB Color+ for decorating labels and flexible packaging. Different finishes can be realized with this.

New applications and still opaque white

HP Indigo and Karlville presented a new solution to streamline pouch production, enabling immediate market introduction for short- and medium-run runs. The HP Indigo Digital Pouch Factory Demo debuts at the show with the HP Indigo 20000 Digital Press and Karlville Pack Ready laminating and pouch-making machines. The turnkey solution facilitates market entry to deliver pouches on demand and in compliance with food packaging regulations in a more sustainable way. HP Indigo ElectroInks can be used for food packaging and are free of UV-reactive chemicals.

The HP Indigo ElectroInk White Ink portfolio has been expanded with HP Indigo ElectroInk Premium White for narrow-web sleeves. The new high-slip white ink can deliver a wider range of opacity levels in a single print process and is specifically designed to help shrink sleeves work more efficiently.

HP Indigo announced a collaboration with Agfa to expand its security portfolio with unique variable data designs for brand protection and security applications.

The HP Indigo GEM, integrated with the HP Indigo 6900 Digital Press, can produce digital spot and tactile coatings, digital films and a range of other creative effects. The one-pass solution requires only one operator and one digital file per job and is expected to be available later this year. Beta testing of the first GEM unit is underway at ILS in the USA. "ILS is a pioneer in HP Indigo digital label and packaging technology. The HP Indigo GEM solution provides the opportunity to disrupt the market with a fully digital variable-decorative printing solution," said Jay Dollries, ILS president and CEO. "This latest innovation offers a wide range of embellishments and creative options. In addition, a new inline metallization solution for digital film production in silver and gold, KURZ DM-JETLINER with the HP Indigo 6900, was demonstrated. This solution simplifies the production of high-quality labels with metallic effects in a single pass on a variety of substrates at full print speed without tools and with less waste compared to the analogue solution.

In addition, a new inline metallization solution for digital film production in silver and gold, KURZ DM-JETLINER with the HP Indigo 6900, was demonstrated. This solution simplifies the production of high-quality labels with metallic effects in a single pass on a variety of substrates at full print speed without tools and with less waste compared to the analogue solution.

Another new ink, HP Indigo ElectroInk Fade Resistant Orange, is now available to complete a seven-colour ink set for outdoor label applications that require high light fastness.

In software, HP introduced PrintOS Enhanced Productivity Mode (EPM) preflight for labels and packaging, replacing manual file analysis and providing an easy way to check PDF file compatibility, among other things, to print 33% faster with three colours. A cloud-based solution is the HP PrintOS Marketplace, which offers on-demand subscriptions to a variety of workflow applications and licenses, among others.

VOC- and solvent-free plate production

Miraclon introduced the Kodak Flexcel NX Ultra plate making process. The water-based processing of the plates, without solvents and VOCs, enables the production of print-ready plates within one hour. Miraclon's patented Kodak Ultra Clean technology, developed by Miraclon, enables the creation of "consistent, high-performance flexographic printing plates in a high-throughput, low-maintenance environment," according to the manufacturer. The KODAK FLEXCEL NX Ultra Solution consists of the FLEXCEL NX System for premium imaging, the new FLEXCEL NX Ultra Conversion System, and the new FLEXCEL NX Ultra Plate. The processing system combines exposure, washout, drying and finishing functions in an easy to use, robust system with automatic cleaning cycles. The new Kodak Flexcel NX Ultra 35 can image plates up to a size of 889 x 1219.2 millimetres.

FLEXCEL NX Ultra plates, available in thicknesses of 1.14 millimetres and 1.70 millimetres, use the proven flat-top dot structure, Kodak NX Advantage technology and patented Advanced Edge Definition, which is available to all users of FLEXCEL NX systems. Chris Payne, CEO of Miraclon, said: "Our rich flexo tradition has led to a track record of technical innovation that enables our customers to grow and succeed. We are focused on meeting complex challenges, and our KODAK Ultra Clean Technology has solved the fundamental challenge of "inconsistency" that traditionally occurs with water-based flexographic plates. This allows printers to take advantage of our industry-leading plate technology without the hassle of solvent processing.