Notwithstanding the huge progress of CI flexo printing over the past 20 years or so, bouncing remains a factor that can affect the quality of a printed job and result in loss of production time and unnecessary waste. Furthermore, to avoid the occurrence of it, a printer may fail to maximize the CI flexo press capabilities by limiting production speed with some applications, hence productivity.

Notwithstanding the huge progress of CI flexo printing over the past 20 years or so, bouncing remains a factor that can affect the quality of a printed job and result in loss of production time and unnecessary waste. Furthermore, to avoid the occurrence of it, a printer may fail to maximize the CI flexo press capabilities by limiting production speed with some applications, hence productivity.

There may be factors that together, can concur to bouncing, but the occurrence of vibrations is no doubt one of the most common contributors. If the contact of the flexo plate with the anilox roller and the substrate is inconsistent, its highs and lows during printing cause the vibrations that affect the print quality.

Other than the reduction of speed, there are different solutions that can contribute to containing the effect of bouncing, such as finding the plates or the tapes that make a printer’s printing process more consistent, along with the stability of the press itself.

The latter is exactly how BOBST has tackled the issue of bouncing on wide-web CI flexo presses: with an advanced press design that offers features that have been specifically developed to eliminate press vibrations.

These include some specific design components:

Sturdy cast iron frame

Top and bottom slide guides for the bearing caps of the anilox roller and plate cylinder

Automatic opening and closing of the bearing caps of the plate cylinders

Carbon fibre shafts, which have advanced physical properties, for plate cylinders

Drive controls that perfectly synchronize the speed of the plate cylinder with the print design

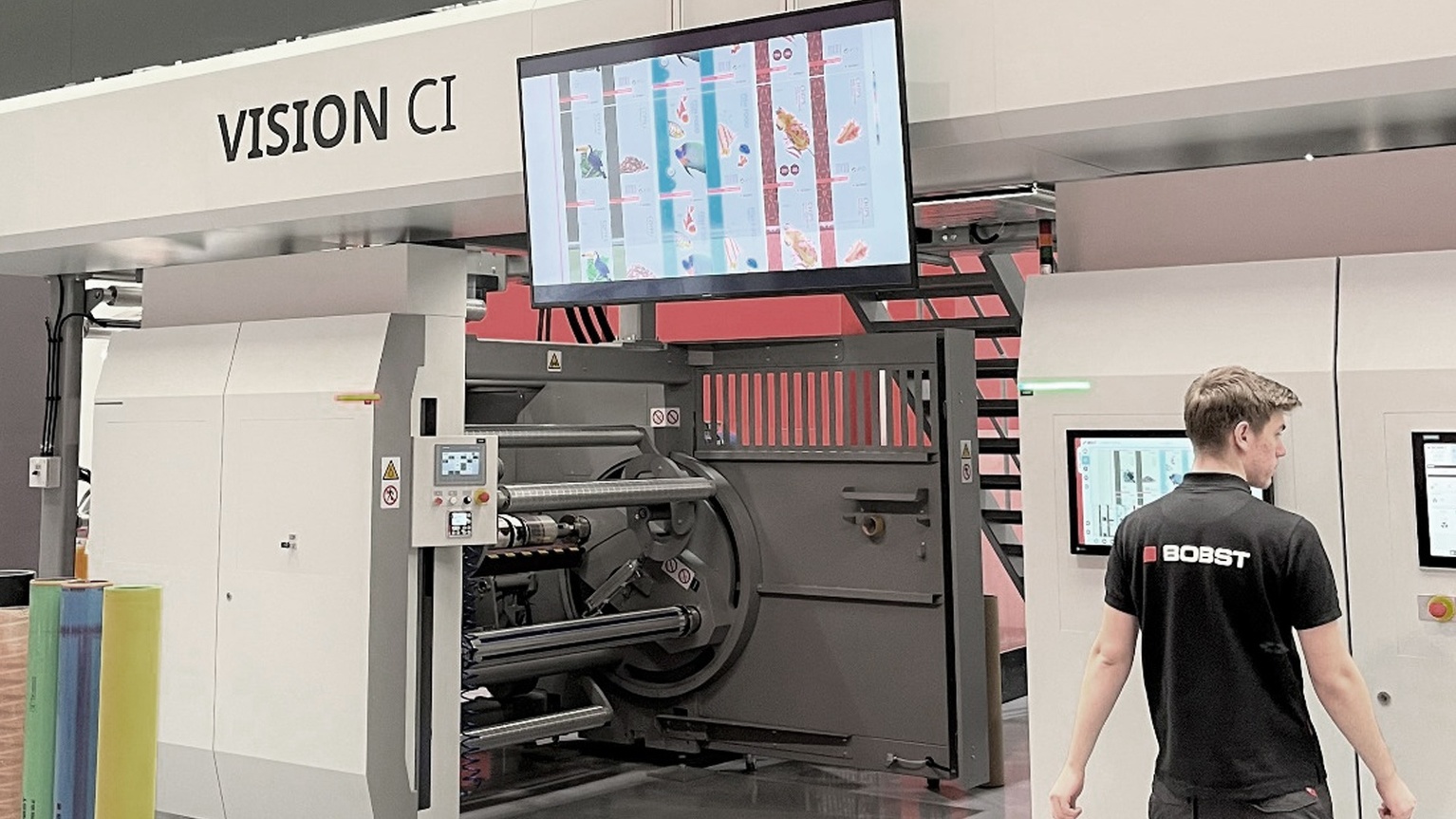

The BOBST VISION CI is a flexo press which combines all of the above features and more. All aimed at enabling production of top print quality at high speed.

The press’ advanced drive control system allows for perfect register control. This means that it is possible to achieve precise alignment of colors and images, resulting in high-quality prints that meet the most precise specifications. The frustration derived from the time-consuming process of readjusting the register is eliminated, along with unnecessary downtime and costs.

Other quality-enhancing and cost-reducing features of the VISION CI flexo press include:

impression setting adjustments by 1 µm

a one-pump inking system for the optimal flow of inks

BOBST advanced CI flexo technology, achieved through the perfect combination and integration of mechanical and electronic features ensures printing consistency and accuracy run after run, giving converters the confidence that the final product meets the highest standards of quality.

www.bobst.com