With the presentation of numerous new digital printer models as World or European premieres, the Hunkeler Innovationdays 2023 offers several highlights. These will be complemented by various workflow integrations such as the inline connection of the Hunkeler Generation 8 roll to stack solution with the Horizon perfect binder or the new Hunkeler Media Changer RX8 that allows for nonstop media roll changes.

With the presentation of numerous new digital printer models as World or European premieres, the Hunkeler Innovationdays 2023 offers several highlights. These will be complemented by various workflow integrations such as the inline connection of the Hunkeler Generation 8 roll to stack solution with the Horizon perfect binder or the new Hunkeler Media Changer RX8 that allows for nonstop media roll changes.

Hunkeler is introducing the new Starbook solutions as part of the Digital Web Finishing brand. Faster, automated quick changeover, and higher productivity are just the beginning of the advantages and features.

The new Sheet Cutter in the DocuTrim allows now to process sheets up to the size of B2+ and makes for the new DocuTrim B2+ in the Digital Sheet Finishing brand.

The new Book Sorting Module BSM is the first module in the Smart Logistics Solutions brand. It allows to sort pre-glued book blocks from various Hunkeler solutions based on different customer defined criteria.

At Hunkeler Innovationdays 2023, 22 Hunkeler solutions will be shown with partners and in total over 50 digital print- and finishing solutions are being exhibited.

New Hunkeler Starbook Plowfolder book solution with Book Sorting Module BSM

The new highly automated Hunkeler Starbook Plowfolder book solution allows for highly economical production of digitally printed books from Book of one. Fully variable page count and variable book spine lengths from book to book at web speeds of up to 250 m/min and semi-automatic changeover of different folding patterns in about 3 minutes make for a great format flexibility for every run length. Excellent book block quality with perfectly straight, square, and flat book blocks make it the quintessential solution for softcover and hardcover books alike. Ease of operation, low maintenance, media flexibility, and the ability to deliver single book blocks at a rate of up to 2000 deliveries (stacks or single books) per hour in perfect FIFO sequence (First In - First Out) makes it the star of the Hunkeler book block machine portfolio.

The new Book Sorting Module BSM is the first module of the Hunkeler brand Smart Logistics Solutions. The modular system sorts up to 2000 book blocks per hour into different transport containers according to customer-specific criteria. The book sorting module can be installed behind all Hunkeler book block solutions.

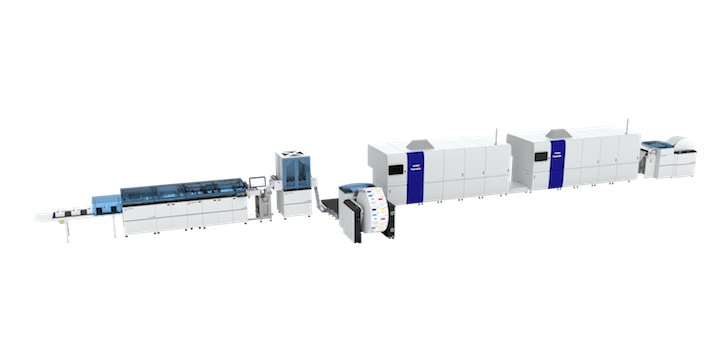

New Hunkeler Starbook Webfolder book solution with Media Changer RX8 and Web Folder WF8

The new Hunkeler Starbook Webfolder book solution is perfectly suited for softcover or hardcover book blocks and catalogues based on 4-page signatures. Fully variable page count and variable book spine lengths from book to book at web speeds up to 180 m/min and an economical price tag make it the second star in the Hunkeler book block machine portfolio.

The modular Book Delivery BD8 guaranties an excellent book block quality with perfectly straight, square and flat book blocks and a performance of up to 2000 deliveries (stacks or single books) per hour in perfect FIFO sequence (First In – First Out).

The system is feed by the Media Changer RX8 that allows printer supported media roll changes with automatic roll splicing of different papers on the fly.

Hunkeler Generation 8 roll to stack solution with loose-leaf sheet stack transfer into the Horizon iCE Binder BQ-500

Time tested Hunkeler Generation 8 roll to stack solution with a new sheet stack transfer station to interface with the Horizon BQ-500 perfect binder.

Production of loose-leaf book stacks and commercial print products like flyers and cards from roll.

Hunkeler Generation 8 roll to buckle-fold solution for Direct Mail with Dynamic Processor DP8 and Horizon folder

Production of Direct-Mailings with coupons and included reply-cards. Production from the paper roll (Unwinder UW8) to a Horizon buckle folder. Dynamically controlled cross and vertical perforations or scoring in a Dynamic Processor DP8. Longitudinal fold in the Web Folder WF8 or transport of the unfolded web using a bypass function. Subsequent cross cutting in the Length and Cross Cutter CS8. Double cross-cutting cylinder for chip out on printed materials with full-bleed motifs or for an optional cross perforation. Transfer of the sheets to the Horizon folding machine. Alternative output to the new Stream Delivery by rolling away the folder and attach the moveable Stream Delivery.

Hunkeler DocuTrim B2+ with new Sheet Cutter for formats up to B2+

Universal sheet processing system Hunkeler DocuTrim B2+ nearline with new Sheet Cutter for high format flexibility up to B2+ sheet sizes. Sheet finishing of mailing products and transactional/transpromo documents for sheet sizes up to B2+. Cutting and dynamic perforations, both lengthwise and crosswise on the sheet format. Chip out for printed materials with full-bleed motifs. Processed sheets are then collected and stacked. The Hunkeler DocuTrim B2+ is able to process sheet formats up to 530 x 750 mm into end products in the format range A3, A4, A5 and A6.

Hunkeler Control Platform

The Hunkeler Control Platform consist of the production quality and content control level where we offer Vision Systems and Control & Tracking Solutions and the machine operating data level where we offer the Hunkeler Data Capture with the optional Hunkeler Analytics tool.

Info Point Vision Systems

With the Web Inspection WI8 we can check the quality and content of the printing on each page in terms of colors, positions, contours, smearing, jet-outs, data validation, etc.

The web inspection system scans the entire width of the paper web, acquiring at full speed high-resolution images on the full surface of each page and comparing them to a related “golden sample” in order to carry out many kinds of quality and contend checks. Printing quality and content errors are identified at an early stage, thereby triggering immediate action and reducing both, downtimes and the amount of wasted paper.

The optional Intelligent Print Inspection (IPI) enables a new way of performing print inspection. IPI uses the raw print data directly from the printer controller to compare to the actual printed image without a “golden sample”.

Info Point Production Control and Tracking Solutions

The production tracking monitors ongoing production in terms of completeness and accuracy. The consistency of ongoing production is constantly compared with the target data and missing pages or duplicates are identified. Defective products can be automatically fed out of the production workflow and missing documents reprinted, thereby facilitating fully automatic operation, and rendering manual controls superfluous. Standardized interfaces enable communication with superordinate systems (host computer) to take place and support monitoring across multiple lines and even multiple production sites.

The available products include Basic Integrity Control, Production Logging and Production Tracking.

Info Point Hunkeler Data Capture and Analytics

The Hunkeler Data Capture, the Hunkeler Workflow Manager HWM Line Plugin and the HLI Gateway form the basis of the Hunkeler operating data network. In the Hunkeler Data Capture, Hunkeler machine operating data is collected from Generation 8 and POPP6/7 modules and can be made available to third-party systems via HTTP Rest or MQTT. Optionally, operating data can be graphically displayed and analyzed in the HWM Analytics plugin.

Info Point Hunkeler Global Customer Services

Hunkeler Global Customer Services offers a full array of customizable services including Field Support, Training, Spare Parts, Technical Support and Professional Services to get the customer up and running faster, reduce downtime, increase productivity, reduce costs with less unplanned down times and increase profitability.

The products Hunkeler Remote Assist and Knowledge Scout help the service provider to react faster and more reliable.

Partner Solutions

New HP PageWide Advantage 2200 press with Hunkeler roll to roll solution

The new HP PageWide Advantage 2000 press sees its European premier at the Hunkeler Innovationdays 2023. The new press is equipped with the well proven Hunkeler Unwinder UW8 and Rewinder RW8.

The press prints a variety of different color applications for direct mail, publishing, and commercial print products.

New Ricoh Pro VC70000e press with Hunkeler roll to roll solution

The new Ricoh Pro VC70000e with a new Undercoater for premium print applications. The color inkjet press is equipped with the Hunkeler winders UW8 (Unwinder) and RW8 (Rewinder)

Ricoh Pro V20100 press with Hunkeler roll to roll solution

The compact Ricoh Pro V20100 mono printer equipped with the versatile Hunkeler Unwinder UW8 and Rewinder RW8. The press showcases a black and white manual application.

Canon ProStream press with Hunkeler roll to roll and roll to stack combination solution

The proven Canon ProStream for high volume, commercial print environments. The finishing combination of the proven Hunkeler roll to roll and the Hunkeler Generation 8 roll to stack solutions give the highest flexibility and versatility in terms of speed and end products. Commercial print end products from cards, flyers, brochures, manuals and posters up to B2+ in size can be cut and stacked in full bleed printing.

Canon varioPRINT iX-series press with nearline Hunkeler DocuTrim

Sheetfed inkjet press from the Canon varioPRINT iX-series for commercial print applications.

Finishing of the printed sheets into direct mailings, cards and flyers nearline in the versatile new Hunkeler DocuTrim B2+ on the Hunkeler booth.

Screen Truepress Jet520HD+ press with Hunkeler roll to roll and roll to stack combination solution

The well-established Screen Truepress Jet520HD+ press for high volume, commercial print environments. The finishing combination of the proven Hunkeler Generation 8 roll to roll and the Hunkeler roll to stack solutions offer the highest flexibility and versatility in terms of speed and end products.

New Screen Truepress PAC520P press with Hunkeler roll to roll solution for paper based packaging products

With the new Truepress PAC520P Screen showcases a new water-based inkjet press for paper based packaging substrates. With it, the flexible packaging industry can reduce its environmental impact by creating more sustainable packaging materials.

The new press is equipped with the well proven Hunkeler Unwinder UW8 and Rewinder RW8.

New Kodak Prosper Ultra 520 press with Hunkeler roll to roll solution and Web Inspection WI8

Kodak Prosper Ultra 520 press, powered by KODAK ULTRASTREAM Continuous Inkjet Technology, equipped with the well proven Hunkeler Unwinder UW8 and Rewinder RW8.

The press will print live three versions of a "magalog" (blend of magazine and catalog) with different editorial and marketing content and is connected with the Hunkeler Web Inspection WI8 for quality and content control.

Xerox cut sheet printers Baltoro and Iridesse with nearline Hunkeler DocuTrim

Xerox Baltoro HF Inkjet Press and Xerox Iridesse Production Press printing a variety of different applications.

The printed sheets will be finished on the nearline Hunkeler DocuTrim.

Bluecrest Epic high speed inserter with Hunkeler Unwinder UW8

Bluecrest high speed Epic inserter feed by the Hunkeler Unwinder UW8.

Meccanotecnica Universe Web book sewing from roll with Hunkeler roll feeder UW8 – CS6-HS

Meccanotecnica book thread sewing solution Universe Web with the Hunkeler roll feeder consisting of Unwinder UW8 and Cutter CS6-HS.

New Horizon Stitchliner Mark V with Hunkeler roll feeder UW8 – CS8

New Horizon stitcher Stitchliner Mark V feed by the high speed Hunkeler roll feeder consisting of Unwinder UW8 and Cutter CS8.

Smart Stitching with a production speed of up to 6000 brochures per hour. Job changes with different booklet thicknesses take place without makeready times.

Horizon Smart Binding - Case Binding System with Hunkeler roll feeder UW6 – CS8

Horizon Smart Binding – Case Binding System roll to book finish configuration with Hunkeler roll feeder consisting of Unwinder UW6 and Cutter CS8.

Production of softcover books and book blocks for hardcover binding in the same line in the iCE Binder BQ-500 with the new components ESF-1000 attachment feeder, GF-500 gauze unit as well as the iCE Trimmer HT-300. Job changeover between the two product types is fully automatic.

New Müller Martini Prinova Digital hybrid saddle stitcher with Hunkeler roll feeder UW8 – CS8

New Müller Martini Prinova Digital hybrid saddle stitcher feed by the high speed Hunkeler roll feeder consisting of Unwinder UW8 and Cutter CS8.

Müller Martini Vareo/InfiniTrim softcover and hardcover book binding solution

Müller Martini Vareo PRO perfect binder for mixed softcover and hardcover book binding combined with the InfiniTrim three-knife trimmer.

Kern K3200 high speed inserter with Hunkeler Unwinder UW8

Kern K2000 high speed inserter feed by the high speed Hunkeler Unwinder UW8.

Xeikon SX30000 with Hunkeler Generation 8 cut-stack solution

Xeikon SX30000 Graphic Arts application printer with the Hunkeler Generation 8 cut-stack solution consisting of the Web Buffer WB8, Cutter CS8, and Stacker LS8.

BOWE SYSTEC Fusion inserter with Hunkeler Unwinder UW8

Bowe Systec high speed Fusion inserter feed by the highly dynamic Hunkeler Unwinder UW8.

www.hunkeler.ch