Sales cooperation with Japanese AN Corporation for Kawahara finishing products

Sales cooperation with Japanese AN Corporation for Kawahara finishing products

Complete workflow for in-mould label and folding carton production available

Heidelberg presents Kawahara stripping system TXS-1100 at Label Day at Wiesloch-Walldorf site

In summer 2021, Heidelberger Druckmaschinen AG (Heidelberg) unveiled the Generation 4 CutStar, the Speedmaster XL 106-D rotary die cutter and a new performance package for in-mould label production on the Speedmaster XL 106. Heidelberg is now expanding its portfolio once again and has entered into a cooperation agreement with the Japanese company AN Corporation for the worldwide distribution of the Kawahara TXS 1100 and Kawahara BMS 1100 automated finishing systems. With this move, the company is rolling out a pilot agreement for the North American region that was concluded last year.

Complete technology for highly efficient workflow

"Heidelberg is consistently investing in the growth markets of packaging and label printing. The sales cooperation for Kawahara stripping systems adds an important production step in the workflow to the company's label printing portfolio," says Rainer Hundsdörfer, CEO at Heidelberg. "We are thus supporting our customers in further automating their processes and making them as efficient and economical as possible."

All in all, Heidelberg thus offers the complete technology for a highly efficient workflow in industrial label production - from job creation, prepress and platesetting, the printing and die-cutting process to the fully automated stripped-out panels.

Kawahara stripping systems with high productivity and established technology

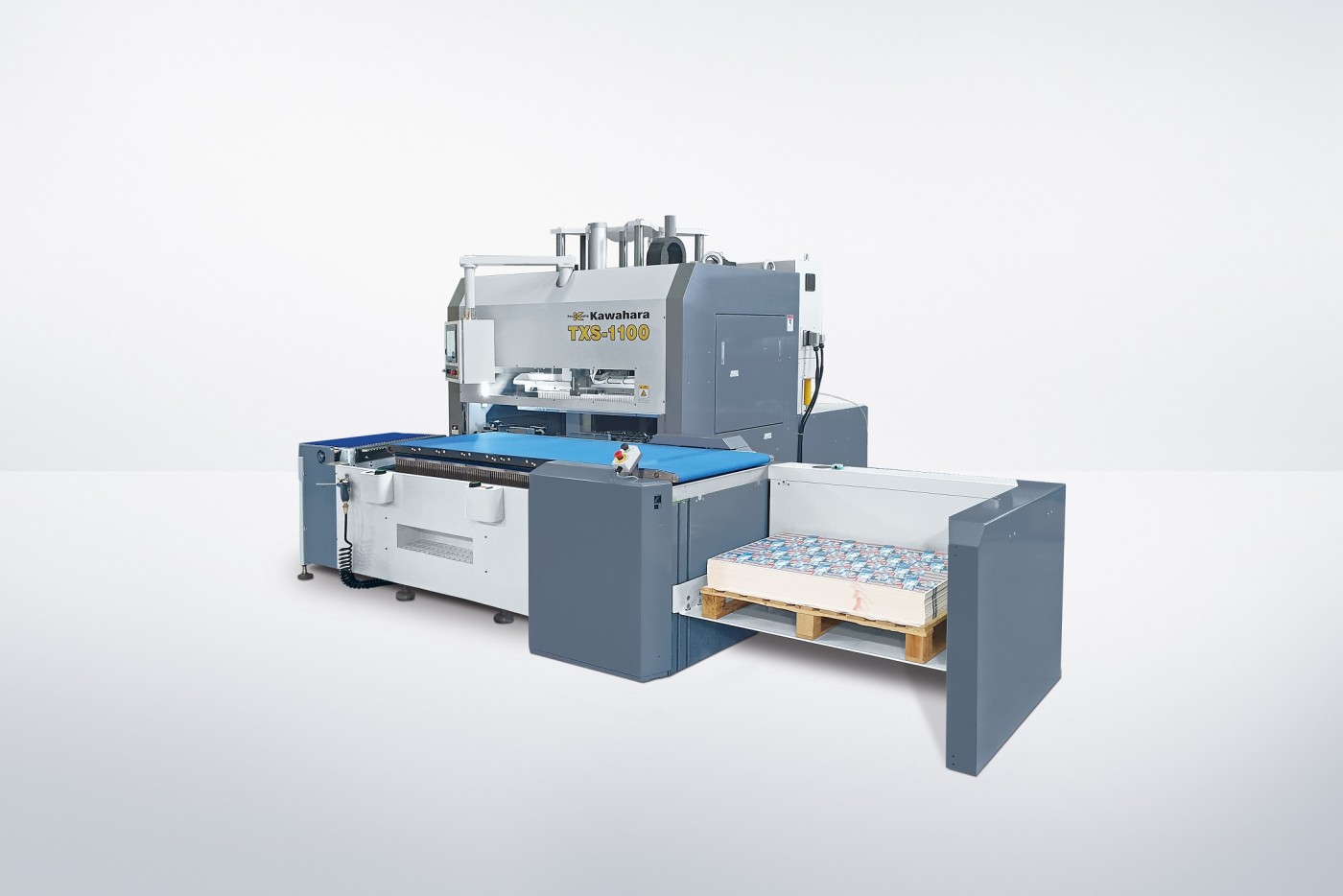

The range includes the Kawahara TXS-1100 and Kawahara BMS-1100 stripping stations. Both models are characterised by their high performance. A job is set up in less than 15 minutes and tooling costs are minimal. On the TXS-1100, a stripping cycle takes between 1.5 and 2 minutes, stripping and unloading layers of up to 1000 in-mould sheets. "The new Kawahara TXS-1100 is a high-performance system and features improved components and a novel feeding and discharge system. It is very well suited to the in-mould label market and has proven to be an excellent solution for stripping and separating this difficult-to-handle material. The Kawahara BMS-1100 offers folding carton printers the opportunity to automate their stripping process at a particularly attractive price/performance ratio," says Markus Höfer, head of the Label Printing segment at Heidelberg. The BMS-1100 can produce up to 20 blank packages with individual contours per minute. It processes both separately standing labels and nested products.

Heidelberg to showcase Kawahara TXS-1100 at Label Day in April

Heidelberg and Gallus will be welcoming customers and interested parties to Label Day at the Print Media Center in Wiesloch-Walldorf on 25 April 2022. Among other things, a complete workflow for in-mould label production will be presented on a Speedmaster XL 106, a Speedmaster XL 106-D rotary die cutter and a TXS-1100 stripping station from Kawahara.

www.heidelberg.com