Whether portioned, packaged or filled - in the mechanical processing of beverages and foodstuffs, it is crucial that seals in machines and systems are hygienic and safe. To ensure this, materials and moulded parts must meet the highest food safety requirements. As a partner for sealing applications, Trelleborg Sealing Solutions supplies a broad portfolio of systems and materials. Find out more at Drinktec 2022 in Munich at stand 426, hall B3.

Whether portioned, packaged or filled - in the mechanical processing of beverages and foodstuffs, it is crucial that seals in machines and systems are hygienic and safe. To ensure this, materials and moulded parts must meet the highest food safety requirements. As a partner for sealing applications, Trelleborg Sealing Solutions supplies a broad portfolio of systems and materials. Find out more at Drinktec 2022 in Munich at stand 426, hall B3.

"Filling lines, processing and packaging machines in the beverage and food industry consist of numerous components and installations. The cleaning processes are correspondingly labour-intensive," says Martin Krüger, Business Unit Manager for Food, Beverage & Potable Water Applications at Trelleborg Sealing Solutions Germany. "This presents plant operators with key challenges: On the one hand, it is necessary to ensure the safety of the food and protect it from contamination or microorganisms. On the other hand, the measures should be associated with little effort in order to keep production costs low." In finding solutions, the sealing specialist from Stuttgart accompanies its customers from the first design to prototypes to the finished solution.

Quicker and easier cleaning with Hygienic Design

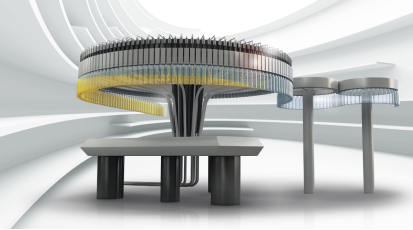

Two challenges can be mastered with the so-called Hygienic Design. When systems are designed according to the principle of hygienic design, they can not only simplify cleaning processes, but also significantly shorten cleaning times. Downtimes can thus be reduced, hygiene standards met and food safety guaranteed.

In the development of its seals for the food and beverage industry, Trelleborg takes a holistic approach: with Hygienic Design, the company covers not only the appropriate choice of materials, but also the design development of the moulded parts. Here, the experts use so-called finite element analysis (FEA) to simulate the behaviour of moulded parts under installation and application conditions. This allows the function of the seal to be improved even before prototype production. Whether made from elastomers, thermoplastics or composites, Trelleborg integrates individual moulded parts into systems and matches them to requirements such as performance, geometry and cost.

With Variseal® HiClean and Variseal® UltraClean, Trelleborg offers highly reliable seal designs used in filling lines in the beverage, food and pharmaceutical industries. The PTFE-based (polytetrafluoroethylene) seals are characterised by low porosity, high pressure tolerance and low friction. They are therefore suitable for use with foodstuffs and are also resistant to aggressive cleaning agents.

High-quality material thanks to Isolast® and EPDM

Especially with frequent changes of beverages or liquid foodstuffs, cleaning is enormously important for systems. For seals, hygienic design ultimately means: avoiding porous or scratched surfaces where micro-organisms and bacteria can settle. This is why Trelleborg developed the perfluoroelastomer material Isolast®. This is practically inert, i.e. chemically inactive to media such as solvents, acids, bases or steam. Thanks to this material, filling systems can be operated safely and hygienically at extreme operating temperatures.

Trelleborg also frequently uses the material EPDM (ethylene propylene diene rubber). Both are particularly suitable for filling lines that are exposed to cleaning processes such as CIP (Cleaning In Place) and SIP (Sterilization In Place).

Andreas Schmiedel, Technical Manager Europe at Trelleborg Sealing Solutions, says: "When developing seals in the food sector, strict guidelines specify what materials or moulded parts must be like. We comply with the central regulations of the international food industry as specified by ISO, EU, DIN, FDA or EHEDG, the European Hygienic Engineering and Design Group."

www.trelleborg.com