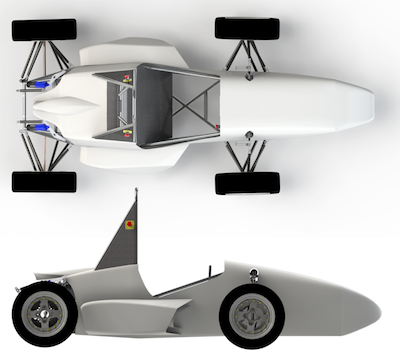

Formula Group T is a project run by Belgian masterstudents engineering from GROUP T who design and build a small electric vehicle (Areion) and compete with other universities worldwide in the Formula Student competitions during the summer of 2012.

Formula Group T is a project run by Belgian masterstudents engineering from GROUP T who design and build a small electric vehicle (Areion) and compete with other universities worldwide in the Formula Student competitions during the summer of 2012.

Formula Group T consists of 16 experienced Master students in Engineering, studying at GROUP T - International University College Leuven near Brussels (Belgium). Formula Group T is a spin-out of the CQS Group T Racing Team that designed and built two alternative drivetrains between 2009 and 2011.

The team was founded in September 2009 and began 'from scratch' with the development of an electric and hybrid race car. Both cars were based on a Citroën 2CV, an icon in the European automotive history. The electric vehicle is called Odyssee. Its front wheels are driven by a switched reluctance motor (SRM). It was the first time a car was equipped with this kind of motor. Lithium iron phosphate batteries deliver the power. The hybrid car, Pegasus, contains the original 2CV engine, adapted with an injection system to run on bio-ethanol (E85). Additional power is unleashed when an extra electric motor in the back is activated. The Kinetic Energy Recovery system provides the car with an optimal drive.

Pegasus participated twice (2010, 2011) in the 24h02'CV race at Spa-Francorchamps where 2CV based cars compete in a 24 hours endurance race. By participating in the race, the team wanted to create awareness in the society for a greener future. This year, Pegasus finished second in the experimental class with the help of one of the best Belgian pilots, Bert Longin.

Pegasus participated twice (2010, 2011) in the 24h02'CV race at Spa-Francorchamps where 2CV based cars compete in a 24 hours endurance race. By participating in the race, the team wanted to create awareness in the society for a greener future. This year, Pegasus finished second in the experimental class with the help of one of the best Belgian pilots, Bert Longin.

A new car means a new name. The name Areion is chosen because it stands for an immortal, strong and swift mythological horse. Strong, swift and immortal are exactly those characteristics we want to achieve with Areion. A fast, agile car which will set history in the future of Formula Group T.

|

|||||||||||||||||||||||||||||||||||||||||

One of the three key-technologies Formula Group T wants to implement in Areion is the use of additive manufacturing techniques. This manufacturing method gives the user the ability to develop a product layer per layer and is often referred to as 3D manufacturing or rapid prototyping.

One of the three key-technologies Formula Group T wants to implement in Areion is the use of additive manufacturing techniques. This manufacturing method gives the user the ability to develop a product layer per layer and is often referred to as 3D manufacturing or rapid prototyping.

A first aspect where this technique can be found in our car is in the production of the uprights of the suspension system. In cooperation with Sirris, Formula Group T gets the ability to design lightweight uprights in a first approach to get the unsprung mass of the car as low as possible. In order to get this practically done, the Electron Beam Melting technique is used. Together with titanium as production material, the use of a micro 3D space frame inside the upright is used to get a very strong and lightweight part. A nice advantage is the extra handling Areion receives.

Layerwise, a company specialised in selective laser melting, will also help the Formula Group T team with the design and production of lightweight and complex components.

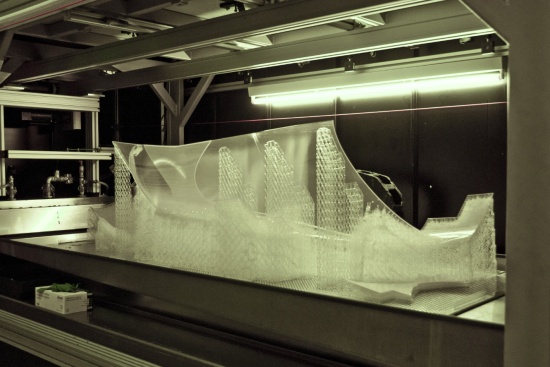

On the other hand Formula Group T cooperates with Materialise to use stereolithography techniques in the production and development of a body enclosure of Areion. Materialise has the unique ability to produce huge components in their so called "mammoth stereolithography" machines. By the use of additive manufacturing in this domain we are able to implement intelligent air cooling to lead cold air from the inlet sidepods directly to the heat source.

Biocomposites

Biocomposites

Formula Group T has already proven concepts in the use of biocomposite materials in race cars. For Areion we wanted to implement these materials in the production of a race seat. In cooperation with Sirris, Centexbel and ITA Aachen, Formula Group T gets the chance to build a biocomposite race seat. The seat will be a demonstrator for a European collective research project between different research centers, as mentioned above. The matrix for the composite seat uses the non oil based polymer polylactic acid instead of the oil based resins which are used in a vast amount of composites. Therefore the seat will have a low carbon footprint. Flax fibers will be used as fiber material since it combines the renewable aspect with good specific properties(strength and stifness/mass).

Electrical drivetrain

An axial flux PMSM from Evo Electric powers the mechanical drivetrain. With only 40kg, it can deliver a peak torque of 600 Nm with a peak power of 167 kW and an efficiency up to 96%. A mechanical gear ratio was chosen, based on analysis of the circuit, to minimize the losses in the motor and minimize the cooling needs. To also decrease power losses in inverter, gearing up with Areion is possible! Switching from Wye to Delta results in a transmission ratio of 1.73 which reduces copper losses in both controller and motor and increases topspeed. While Formula Group T designed the mechanical system with contactors, Triphase programmed the switching sequence on their controller. This Delta-Wye swithing can be done while driving and happens in only a few milliseconds so the driver won't even notice.