By Aditya Chandavarkar

By Aditya Chandavarkar

Digital textile printing continues to push not only boundaries of innovation but also business alliances. 2014 seems to be a year of consolidation and acquisitions for the digital textile printing industry, which could intensify the competition in the industry to offer more comprehensive technology and services to the industry.

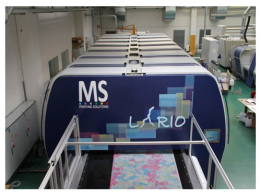

Earlier this year Dover announced their acquisition of Italy-based MS Printing Solutions S.r.l. They are a leading designer, manufacturer and distributor of innovative digital ink jet printing systems and has been in the forefront recently due to the launch of their MS La-Rio single pass printer with a top speed of 70 m/min. Some of its early adopters being the famous Italian textile conglomerate Miroglio group and Menderes Tekstil in Turkey. Menderes Tekstil truly believes that with the advantages of lower water usage, reduced energy consumption & faster turnaround times – The future of home textiles is digital textile printing. Dover is a diversified global manufacturer with annual revenues approaching $8 billion and will bring in the necessary financial muscle for MS s.r.l to concentrate or further evolving the digital textile printing technology and bring in new innovations. Dover focuses on delivering innovative equipment and components, specialty systems and support services to its global industrial end-markets.

Ink companies also are considering strategic consolidation to strengthen their position in the market. Kiian Digital and J-Teck3 have announced in a press release recently that they are joining forces to create a new Group with extended capability and greater resources to meet the challenges resulting from the growth of the digital printing sector. J-Teck3, which has just celebrated its tenth anniversary, has a technologically driven business approach that permits rapid development of new products. J-Teck3 has brought to market a wide variety of disperse, sublimation and pigment inks for printing.

Ink companies also are considering strategic consolidation to strengthen their position in the market. Kiian Digital and J-Teck3 have announced in a press release recently that they are joining forces to create a new Group with extended capability and greater resources to meet the challenges resulting from the growth of the digital printing sector. J-Teck3, which has just celebrated its tenth anniversary, has a technologically driven business approach that permits rapid development of new products. J-Teck3 has brought to market a wide variety of disperse, sublimation and pigment inks for printing.

Kiian Digital has a long history of providing chemicals and digital inks and is regarded as the trusted commercial and technical partner in over 90 countries worldwide.Combining the two companies' strengths leads to a significantly increased global coverage to all key segments with a joint portfolio of inks that is compatible with a wide variety of digital print heads. Maintaining its focus on high quality industry standards and on driving market expansion internationally, the new Group will give the customer base the benefits of a combined R&D and customer service. Reportedly both management teams, including the former J-Teck3 owners, will continue to be fully involved in the ongoing development of the business.

SPG Prints Group previously known as Stork Prints one of the pioneers in digital textile printing has also been considering walking down the acquisition alley with the Investcorp agreeing to acquire SPG Prints. Mr. D.W. Joustra, Chief Executive Officer of SPGPrints believes that "Investcorp is a complementary partner for SPGPrints and one that will provide us with the solid capital base required to help us realise the full growth potential of the business, including through add-on acquisitions." Established in 1947, SPGPrints is the leading global provider of integrated solutions for rotary screen and digital printing for textiles and graphic applications, and the leading manufacturer of precision metal components for a broad range of applications. This will definitely bolster the product development at SPG Prints, namely; the commercial launch of their pigment ink range for wideformat printing & the much awaited single pass printer. SPG Print claims that this technology with revolutionise digital textile printing.

The next phase in digital textile printing technology will depend on stabilising existing technology, chemistry & making single pass technology economically viable. It will be important that the various stakeholders of the industry including OEMs, ink manufacturers & printhead manufactures work together. The technology will also look at sustaining the growth rates it is achieving in fashion, soft signage & also look at penetrating newer markets like home furnishing & interior decoration. InfoTrends research indicates that about 370 Million square meters of digitally produced fabrics in garment, decor, and industrial applications were manufactured in 2013, and the trend is for more rapid growth in the future. All these developments seem to further evidence the fact that digital textile printing will continue to grow and it will gain in importance in the years to come. The race seems to be intensifying and the digital textile printing space is definitely becoming more interesting with the second wave of the technology coming !

The next phase in digital textile printing technology will depend on stabilising existing technology, chemistry & making single pass technology economically viable. It will be important that the various stakeholders of the industry including OEMs, ink manufacturers & printhead manufactures work together. The technology will also look at sustaining the growth rates it is achieving in fashion, soft signage & also look at penetrating newer markets like home furnishing & interior decoration. InfoTrends research indicates that about 370 Million square meters of digitally produced fabrics in garment, decor, and industrial applications were manufactured in 2013, and the trend is for more rapid growth in the future. All these developments seem to further evidence the fact that digital textile printing will continue to grow and it will gain in importance in the years to come. The race seems to be intensifying and the digital textile printing space is definitely becoming more interesting with the second wave of the technology coming !

The pace of development in digital textile printing has lead to organisations developing knowledge transfer platforms and conferences to understand and assimilate the market trends of Digital Textile Printing. 2014 has already seen Digital Textile events from WTiN & Inkjet Forum India.

September & October will see back-to-back digital textile conferences by Unitex & FESPA respectively with support from Inkjet Forum India & other industry leaders. The Unitex conference intends to bring forward the best research, latest developments on digital technologies, including hardware, software, digital inks, printed materials and their related applications. Whereas, FESPA is bringing together a gathering of textile experts who will share trends, technology, and innovations that influence the future of digital textile printing. Inkjet Forum India is a leading digital textile printing knowledge transfer platform in Asia, which organises conferences for updating the industry with the latest market & technology trends.