High quality, innovation, speed of service and customer care are the pillars of the corporate strategy that has accompanied Graphicscalve's journey for over 40 years. The latest investment, to continue the development and growth of the business, is a Komori System 38 rotary press.

High quality, innovation, speed of service and customer care are the pillars of the corporate strategy that has accompanied Graphicscalve's journey for over 40 years. The latest investment, to continue the development and growth of the business, is a Komori System 38 rotary press.

Graphicscalve was born in the late 70s as an artisan typography from an entrepreneurial idea of the brothers Ezio and Walter Ferrari, driven by an authentic passion for printing and an unmistakable charisma.

With great pleasure, we’ve embarked on an exciting journey to explore Komori’s vision at the occasion of the celebration of our 100th anniversary. We’ve shared insights of the trends and challenges in the printing industry for both commercial and packaging, and presented Komori's latest solutions and technologies that support the printers to address them by enhancing their productivity and quality and automation.

With great pleasure, we’ve embarked on an exciting journey to explore Komori’s vision at the occasion of the celebration of our 100th anniversary. We’ve shared insights of the trends and challenges in the printing industry for both commercial and packaging, and presented Komori's latest solutions and technologies that support the printers to address them by enhancing their productivity and quality and automation. Development of new products for further automatisation of the cash circulation

Development of new products for further automatisation of the cash circulation Next step toward digital innovations in the high-security sector

Next step toward digital innovations in the high-security sector Camera-based inspection of front and back of metal sheets

Camera-based inspection of front and back of metal sheets Attendees flocked to the Pulse Roll Label Products (Pulse) booth at Labelexpo Europe last week to learn how Monolox® Fixed Anilox Printing and the PureTone® ink range are revolutionising flexo label printing.

Attendees flocked to the Pulse Roll Label Products (Pulse) booth at Labelexpo Europe last week to learn how Monolox® Fixed Anilox Printing and the PureTone® ink range are revolutionising flexo label printing. High impact and quality in screen-printed products for highly competitive consumer markets

High impact and quality in screen-printed products for highly competitive consumer markets New partner agreement creates better service and support for customers

New partner agreement creates better service and support for customers By John Freismuth, President, Empire Screen Printing

By John Freismuth, President, Empire Screen Printing Both new and upgraded presses deliver next-level quality and speed

Both new and upgraded presses deliver next-level quality and speed Highest automation and considerably shorter makeready times

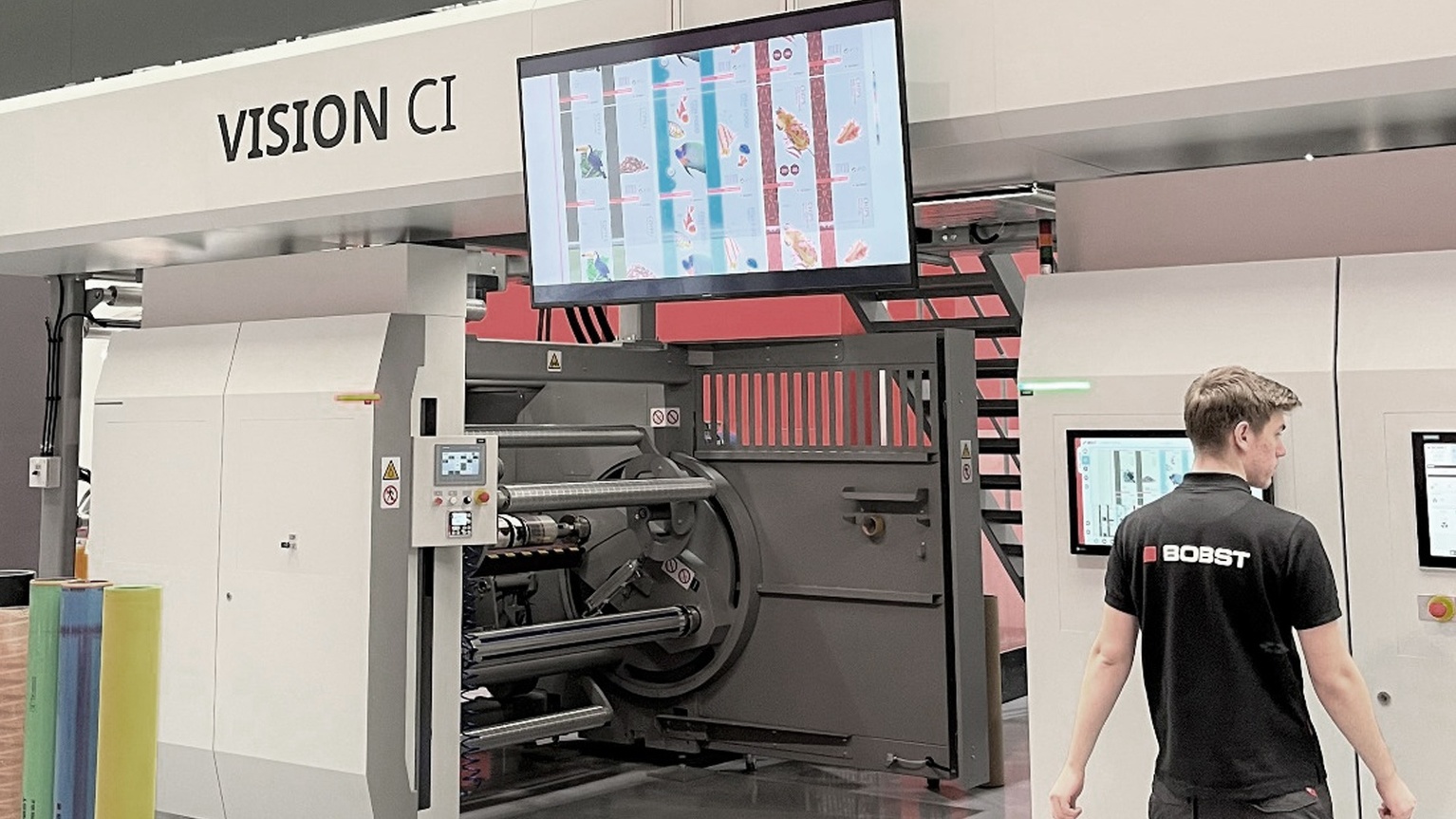

Highest automation and considerably shorter makeready times Notwithstanding the huge progress of CI flexo printing over the past 20 years or so, bouncing remains a factor that can affect the quality of a printed job and result in loss of production time and unnecessary waste. Furthermore, to avoid the occurrence of it, a printer may fail to maximize the CI flexo press capabilities by limiting production speed with some applications, hence productivity.

Notwithstanding the huge progress of CI flexo printing over the past 20 years or so, bouncing remains a factor that can affect the quality of a printed job and result in loss of production time and unnecessary waste. Furthermore, to avoid the occurrence of it, a printer may fail to maximize the CI flexo press capabilities by limiting production speed with some applications, hence productivity.