3D printing is extremely popular these days. Everyday new products, which are printed, are presented throughout different industries. From a table in your house to customized clothing, almost everything can be 3D printed. With this 3rd manufacturing revolution, 3D printing applications for business to business markets arise.

3D printing is extremely popular these days. Everyday new products, which are printed, are presented throughout different industries. From a table in your house to customized clothing, almost everything can be 3D printed. With this 3rd manufacturing revolution, 3D printing applications for business to business markets arise.

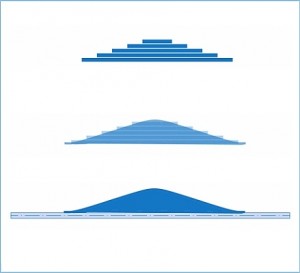

However, there are some issues with regular 3D printing methods. With the most standard 3D printers it is inevitable that you will see layers on the end product. Transparent 3D printing is quite hard without layering. For 3D printed optics a traditional printer cannot be used. At LUXeXceL we developed a unique printing technique which makes transparent 3D printing possible without layering.

Printed Optics: smooth surface 3D printing For many product designs, the layering caused by most fused material printers is tollerable, but for certain products layers are undesirable.

For many product designs, the layering caused by most fused material printers is tollerable, but for certain products layers are undesirable.

Lenses or products that need optical functionality need to be 100% smooth to function, also the fusing of the material cannot leave layers because light needs to travel uninterupted trough it without scattering.

For this reason, 3D printers could never be used for the manufacturing of optical components. They would simply not work.

As an engineer or designer it is key that the light distribution of your optic suits the end product perfectly. LUXeXceL developed a special 3D printing method called Printoptical Technology. This technology is capable of printing fully smooth and transparent surfaces ideal for manufacturing custom optics. But also other transparent plastic items could be printed for example smooth transparent structures. Traditional 3D printers with layers are not capable of creating fully smooth optics.

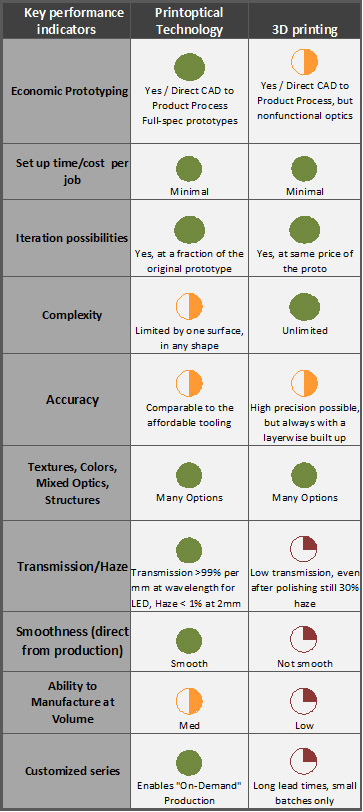

In the infographic 3D printing is compared with our Printoptical Technology in regards to the manufacturing of smooth transparent products.

As shown above, regular 3D printing is not perfectly applicable for manufacturing optics. The needed smooth surface and special textures are key for manufacturing a fully functional optic. With the LUXeXceL Printoptical Technology, manufacturing optics with a complete smooth surface is possible within days. So, if you want to develop a transparent and smooth design, what should be printed in days. Feel free to contact us and try our Printoptical Technology for your transparent 3D printing of optics.

www.luxexcel.com