Due to new technologies like 3D printing, rapid prototype manufacturing becomes the standard throughout different industries. When it comes to prototyping optical elements, mostly smaller quantities are required. Until the uprise of the 3D printer only manufacturing methods that were more suitable for larger volume production were available in most industries.

Due to new technologies like 3D printing, rapid prototype manufacturing becomes the standard throughout different industries. When it comes to prototyping optical elements, mostly smaller quantities are required. Until the uprise of the 3D printer only manufacturing methods that were more suitable for larger volume production were available in most industries.

Common methods like injection molding, embossing or milling were used to prototype optics. In order to be cost effective, thousands of lenses and optical components had to be produced. If you are a small company and you only need a few prototypes that you need to vary in order to come to your desired result, these methods are too costly. But what other methods are there around to provide a solution to this problem? When it comes to optics prototyping, the unique Printoptical Technology by LUXeXceL could help you out.

Optics manufacturing with Printoptical Technology

In order to produce prototypes of your optical elements without the need for molding, you could choose for 3D printed optics. With our 3D printing process it is possible to print your optics on demand. With the short manufacturing period of a maximum of 10 days, you will be able to test your own prototype rapidly.

This means you will no longer be depending on lens manufacturers that apply traditional optics manufacturing methods.

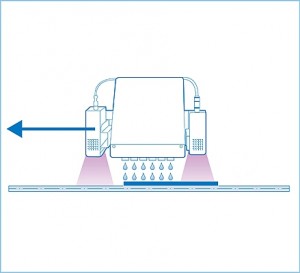

Printoptical Technology stands for a special approach on 3D printing. Instead of printing layer by layer, Printoptical Technology uses small droplets which are cured by UV light. In this way, you can print your optic transparent and smooth without any post-processing.

On top of that we offer optical coatings that will make your 3D printed custom optic suitable for outdoor use, protecting it from UV radiation.

Benefits of using a 3D printer for prototype manufacturing

Benefits of using a 3D printer for prototype manufacturing

The benefit of using a 3D printer for prototype manufacturing is that you can iterate and customize your product on the go. If a prototype does not work out the way you wanted, just edit your CAD-file and use LUXeXceL's Printoptical Technology to have another prototype manufactured. In this way, you can do extensive optics testing in a small timeframe. And in the end you will get your fully customized optical component. A redesign with older manufacturing processes, like injection molding, would cost a vast amount of money. By being able to adjust your CAD-file you can easily modify your optical component or lens. Normally it would take weeks to modify the mold you had initally ordered. Not to speak about the material waste that it would cause. The entire optics fabrication process benefits when the prototyping stage can be done more effectively and economically.

Changing the manufacturing process

gWith the coming of the 3D printer, all manufacturing is changing. For the optics industry it means a very big change. Now any optics designer can order his design in the blink of an eye, only to validate it. This is a big contrast compared to the huge investments that used to be standard for the creation of any single optical component. When using either diamond turning or injection molding for optics, your initial investments are alweays going to be high, making optics testing or prototyping economically difficult.

In the lighting industry, its often the lighting image that needs to be tested. Functional optics testing is now easy which allows for the creation of custom lighting images.

All sorts of lens types can be made using 3D printing, such as diffrative optics, beam shapers, micro lenses, convex, and concave lenses diffusors and so on.

www.luxexcel.com