Wallpaper production is one of the areas that up to now has been largely left untouched by the digital revolution. This is about to change. Xeikon’s dry toner offerings and wallpaper substrates from Felix Schoeller Group enable viable high quality production of individualised outstanding designs for short and medium sized orders. By Sabine Slaughter

Wallpaper production is one of the areas that up to now has been largely left untouched by the digital revolution. This is about to change. Xeikon’s dry toner offerings and wallpaper substrates from Felix Schoeller Group enable viable high quality production of individualised outstanding designs for short and medium sized orders. By Sabine Slaughter

Characterised by the requirement to order large run lengths, mostly in excess of thousands of meters, due to usage of analogue printing processes, a tedious set-up process of the press, long time-to-market and production time, individualised wallpapers, one offs, have not been realised often.

Some market participants are using inkjet-based large format printers, latex- or waterbased to realise individual designs – mainly photo wallpaper projects, prototypes or very short run production. Sure, inkjet printing enables faster job turnaround than gravure or screen printing of wallpapers. However, neither the speed nor production output is enough to satisfy customers that require cost-efficient production of personalised, branded wallpaper in the small to medium range. Branding is everything in the hospitality, retail and many other industries. This does not only encompass a logo, letterheads etc. Ideally the customer shall recognize the brand’s location even from afar. He wants to recognize the brand latest as soon as he approaches and enters the store, hotel or, office, supermarket. This includes a feeling of “home away from home” by experiencing a certain atmosphere, look and also design. Here individualised wallpapers play a crucial role in achieving this aim.

Branding is everything in the hospitality, retail and many other industries. This does not only encompass a logo, letterheads etc. Ideally the customer shall recognize the brand’s location even from afar. He wants to recognize the brand latest as soon as he approaches and enters the store, hotel or, office, supermarket. This includes a feeling of “home away from home” by experiencing a certain atmosphere, look and also design. Here individualised wallpapers play a crucial role in achieving this aim.

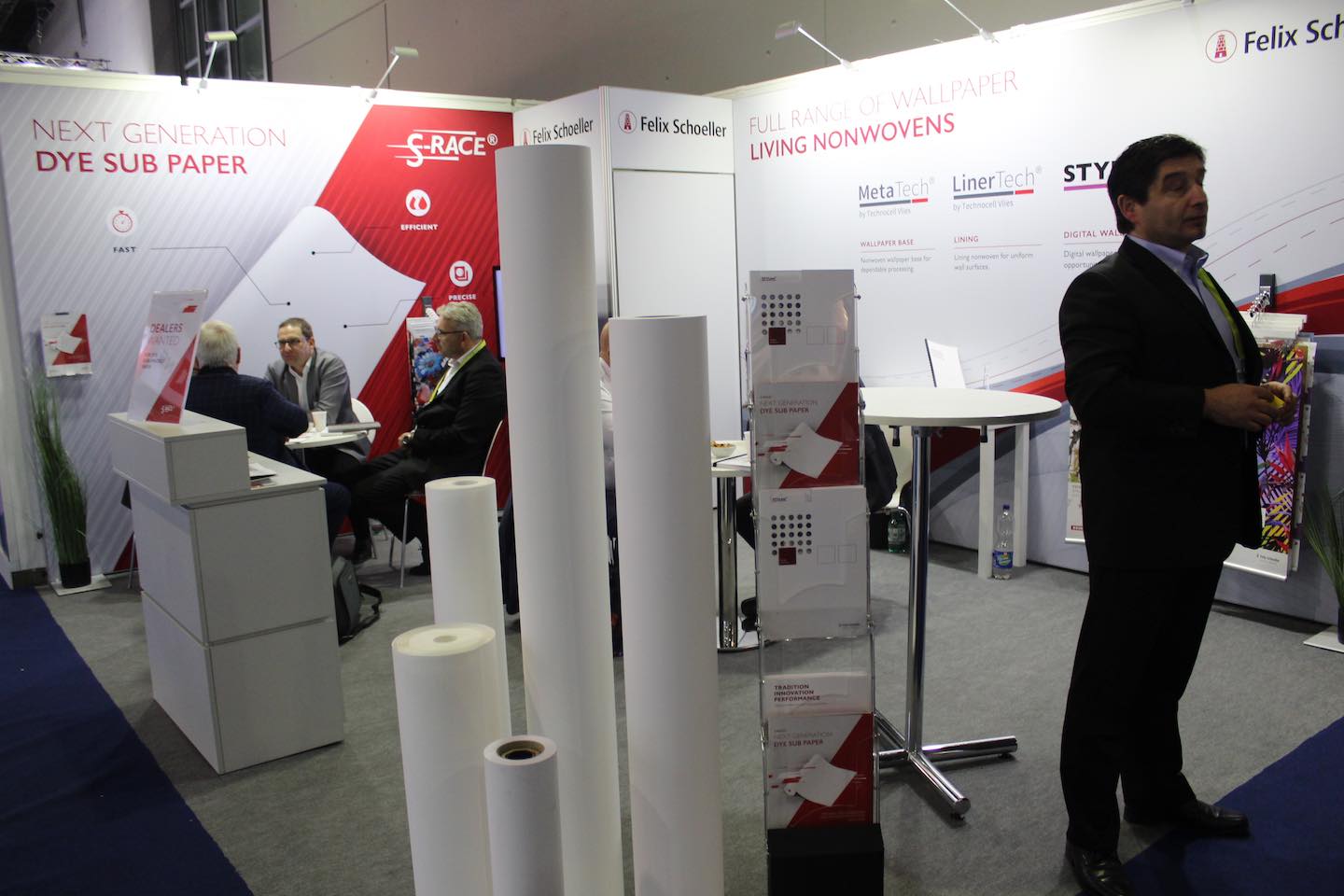

Production of wallpapers with Xeikon’s dry toner technology eliminates most of the hurdles surrounding individualised production. Different suppliers such as Felix Schoeller whose media can be printed on digitally, enable a variety of wallpaper solutions and applications – also for Xeikon presses. At Heimtextil both companies teamed up to showcase applications and ease of use of the Xeikon Wall Deco Suite encompassing workflow software, press and finishing equipment.

Felix Schoeller, as a family-owned company with its headquarter in Osnabrück, produces high quality speciality and décor papers on 22 paper machines woldwide–. 125 years old, the company is committed to sustainable business practices, uncompromised quality and works in partnership with their customers to develop tailored solutions together as well as to manufacture and supply all kinds of speciality papers for photographic applications, digital printing systems (e.g. wallpaper and signage applications), the packaging market, self-adhesive applications and for the furniture industries. “Market demands from today and tomorrow require flexible and optimal media solutions for continuously changing business models”, explains Karin Mair, Head of non-woven at Felix Schoeller., as analogue and digital manufacturing and sales processes merge more and more. The market is influenced by global mega trends like on-demand production, enabling of small batch sizes, product and storage costs, demand for individualisation and digitalisation as well as environmental aspects. These are some of the challenges companies are facing, according to Karin Mair.

“Market demands from today and tomorrow require flexible and optimal media solutions for continuously changing business models”, explains Karin Mair, Head of non-woven at Felix Schoeller., as analogue and digital manufacturing and sales processes merge more and more. The market is influenced by global mega trends like on-demand production, enabling of small batch sizes, product and storage costs, demand for individualisation and digitalisation as well as environmental aspects. These are some of the challenges companies are facing, according to Karin Mair.

Extensive knowledge combined

While the requirements differ between analogue and digital printing technology providers and customers, offering of more divers product ranges and combination of analogue and digital services are on high demand. Within the analogue sector, wallpaper manufacturers focus on non-woven base substrates for diverse analogue applications, which are about 95% of the wallcoverings market worldwide today - SMITHERSPIRA2018.

Within the digital printing arena, print service providers (PSPs) and distributors among others require non-woven media with special coatings and converting for digital printing to reach the desired quality. , says Karin Mair. In order to cater to these demands, Felix Schoeller now has assigned its Digital Media and Technocell Vlies departments to its non-woven business area to pool its expertise in these substrate offerings for analogue and digital usage.

New substrates for Xeikon presses

The analogue line of media such as MetaTech and LinerTech are thus experiencing the same expertise as the STYLine for digital printing processes on Xeikon presses. Apart from uncoated non-woven substrates (Hamburg line) of the STYLine product, special coated non-wovens (New York line), new silver/gold metallic coated non-wovens (Vegas line) and new special coated embossed non-wovens that “look like Vinyl” (Oslo line) are available. All of these four lines of media for wallpaper printing on Xeikon presses are also available with self-adhesive backside coating.

The above mentioned wallpaper lines as well as further media from other manufacturers are an essential part of Xeikon’s offering for the market. “Qualified media means that we can guarantee a smooth pass through our presses”, says Dimitri van Gaever, Market Segment Manager Graphic Arts Digital Solutions at Xeikon. “The wide variety of substrates enables our customers to offer more than just simple wallpaper printing by either themselves or their clients chosing the right media for each job thus surpassing customer expectations.” Four different presses available

Four different presses available

The Xeikon X3500, X3050, X8500 as well as the CX500 can be obtained with the Wall Deco Suite. The first comprises of a Jumbo unwinder suited for rolls up to 850 kg and a diameter of 1,500 mm, a webcleaning unit, the Xeikon X3500, a web varnishing module (AQ WVM), slitting and waste extraction as well as a wallpaper medium rewinder (WMR) with integrated rotary cut and an option of implementation of a rehumidification unit. This solution can produce with speeds of up to 600 sqm/h and is designed to cater to printers whose core business is wall decorations looking for a high volume digital press. The high end digital walldeco press features Xeikon’s unique dry toner technology with the application tuned toner, true 1,200 dpi resolution with four-bit variable-dot density print and an imaging width of 508 mm. Automatic density/register control, contact fusing on the alpine fuser drum and Xeikon’s proven LED array for dry toner electrophotography are further features of the 5/0 single pass press. All this culminates in high-definition images and smooth tone transitions on a wide range of substrates with a matte finish.

A new dry toner platform, proven LED-array and web widths between 250 – 520 mm with a maximum imaging width of 508 mm an speeds of up to 936 sqm/h are some of the features of the Xeikon CX500. Also a 5-colour single pass press, it offers 1,200 dpi resolution resolution with four-bit variable-dot density print, automated and closed loop controls of density, register and color gamut as well as the dedicated toner for higher speeds. Designed for print shops and wallpaper factories that already employ conventional production and are looking for a high volume digital press the CX500 is the alternative for short and medium run production of wallpapers – either personalised, branded or individualised but also catering to fast proofing requirements for clients that would like to see an immediate result of their designs. Both presses can be equipped with a fifth color such as orange, blue, green, red or ExtraMagenta as well as special spot colours or even customer defined colours. Within the CMYK colour range already 72% of the pantone range at a deltaE2000 of 3 can be covered.

Both presses can be equipped with a fifth color such as orange, blue, green, red or ExtraMagenta as well as special spot colours or even customer defined colours. Within the CMYK colour range already 72% of the pantone range at a deltaE2000 of 3 can be covered.

Online printers, PSPs whose would like to enhance their core business of wall decorations and who want to build up volume can be catered to with the Walldeco entry level digital solution, a Xeikon X3050 that achieves speeds up to 290 sqm/h whereby a speed upgrade is possible.

All round PSPs who have a variety of clients for applications in the Graphic Arts sector who look for higher productivity than inkjet solutions can provide are catered to with the Xeikon X8500 that achieves a speed of 360 sqm/h.

No restrictions on repeat length or frame size

All Xeikon dry toner presses feature the patented water-cooled LED array module delivering 1,200 dpi native resolution and a 1,200 x 3,600 dpi addressability whereby 1,200 LEDs per inch on the array module enabling 9 gray levels each at 21µm dot size. The latent image that is written on the OPC drum offer full rotary thus no repeat length or frame size apply.

A Gloss Enhancement Module (GEM) is available for the Xeikon 3000 press series is available and can be used to calender the printed surface of the substrate. A spectrometer is mounted on the cooling roller at the end of this unit to measure toner density and register.

X-800 Workflow

Extensive easy-to-use prepress functionalities, advanced colour management as well as seamless integration and connectivity with 3rd party workflows, MIS, W2P and an automated “poster layout” function for murals enable PSPs to keep their existing prepress equipment and software while at the same time enhancing capabilities.

Toner to match applications

Xeikon’s toner for wallpaper applications has been specifically developed by the company and is produced in Belgium. It contains no VOC, is odourless, eco-friendly and safe to dispose of as well as EN 15102 compliant. It features a high light fastness (6-8 on Blue Wool Scale) and can be obtained in CMYK+white, as off the shelf colour as well as in orange, red, blue green, E. magenta and clear.

As dry toner does not contain any solvents or dangerous chemicals and is waterless no evaporation occurs. In addition, it is food compliant, features no ink penetration which serves the requirement for low paper grammage and has a large substrate compatibility and lightfastness. One of the most sustainable treats however, is the possibility of deinkability making it perfect for paper recycling without additional costs as no separate waste stream is required. Benefits and savings galore

Benefits and savings galore

In comparison with conventional technologies (gravure, screen, offset) as well as inkjet (Latex, UV, etc) significant savings can be achieved on small and medium print runs. Depending on the job a reduction of up to 40% or even 60% costs can be experienced. In addition, shorter runs can be cost-efficiently and –effectively produced. Customisation and individualisation offer further business opportunities especially as print customers can thus always follow the actual trend. Short turnaround times of job including delivery times add to the benefits of digital wallpaper printing with a Xeikon press, explains Dimitri Van Gaever.

While traditional analogue printing of wallpapers requires set-up and make-ready time and costs as well as a minimum run length of the job due to cost-efficiency they also mean that the PSP and the print customer has to store their printed wallpapers as not many will use up those long print runs straight away. Thus additional costs occur.

As the lifetime of a wallpaper design collection is approximately two years and a short run is typically 300 rolls of roughly 10 m per roll, EOL collections/Trials/Start up collections are rarely cost-efficient as well as the printing of sample books and photo-murals. Here Xeikon’s Wall Deco Suite enables to just print the exact amount of rolls or run-length required, saving waste as well as money.

Xeikon Wall Deco SolutionUltra-short runs produced on an inkjet printer mean a slow print speed, quite often VOCs, odour, register, size issues which require additional cuts and, depending on the used ink no or only restricted deinkability which requires separate waste collection. In addition, the PSP will have to decide in advance before the purchase which colours – apart from CMYK – shall be implemented in the printer as it is not possible to change either the type of ink nor the colours afterwards. Once bought and in use, the PSP has to stick with what he bought. Xeikon presses in comparison offer the possibility of switching the toner container in the 5th slot of the press (and also in the CMYK slots, though it does not make much sense) according to the requirements of the job or the print customer, thus enabling all kinds of colour combinations, including spot colours. In addition, dry toner is safe, reliable, easy to handle and its repeatability (register and colour) is unsurpassed in comparison with inkjet, states Dimitri Van Gaever.